39

8.

设定选购项

PERFORMING OPTIONAL SETTING

(1)

选购项设定的变更方法

Changing procedure of the optional setting

1)

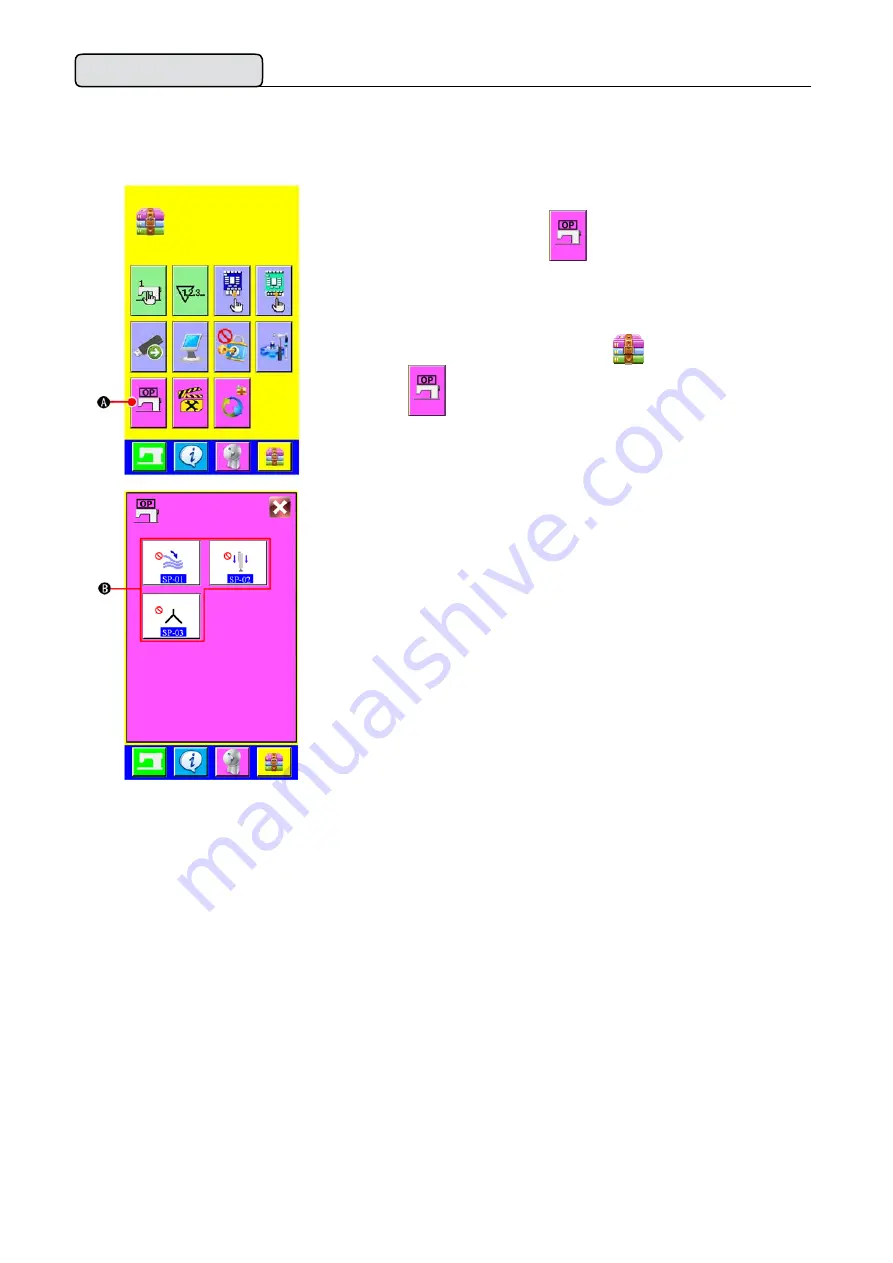

显示设定选购项一览画面

在画面上按设定选购项按钮

○

A 之后,设定选购项一览画面

(画面A)被显示出来。

Displaying the optional setting list screen

Pressing MODE CHANGEOVER key

, OPTIONAL SETTING

button

○

A

is displayed on the screen.

Press this button and the optional setting list screen (screen A) is

displayed.

设定选购项一览画面

(

画面

A)

Optional setting list screen (screen A)

2)

选择想变更的选购项设定

请选择想变更的数据项目按钮

○

B 。

Selecting the option setting you want to change

Select DATA ITEM button

○

B

you want to change.

Summary of Contents for JK-T5878-58G

Page 19: ...16 2 EXPLANATION OF THE BASIC SCREEN A B C D E F G No No H I J K L M N 9...

Page 32: ...29 2 1 No S09 50mm S10 0 30mm S09 20mm S10 5mm...

Page 65: ...62 4 E01 E02 E03 E04 E05 E06 U U U E07 E08 E09 E10...

Page 66: ...63 E12 E13 1 2 E14 E15 E16 E17 E18 E21 E22 E23...