CONFIDENTIAL

PROJECT NAME

| date

项目名称

|

日期

17

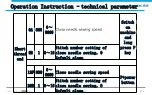

cursor remove

Right move select: parameter setting, the

parameter value needs to reduce the key, the right

cursor right move button at the standby interface.

Left shift select: parameter settings, parameter values

need to increase the key, the standby interface cursor

left shift key.

PROJECT NAME

| date

项目名

称

|

日期

CONFIDENTIA

L

17