ELECTRICAL

The electrical wiring should be independent of all other ac-

cessories. It should be made with marine grade copper

stranded wire of the gauge specified in the electrical spec-

ifications chart. Make all wire connections with mechanical

locking type connectors (crimp type butt connectors and

terminals). Ensure the circuit is protected by a proper sized

fuse or circuit breaker determined from the electrical spec-

ifications chart. Secure all wires to a solid surface approxi-

mately every eighteen inches (1/2 M) along their entire

length of run.

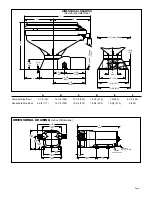

Wire the switch panel to the PAR-MAX rinse pump and toi-

let waste pump as per the following wiring diagram. The

brown lead from the control panel connects with the waste

pump orange (positive) motor lead. The yellow lead from

the control panel connects with the PAR-MAX rinse water

pump orange (positive) motor lead. The black motor lead

from each pump must be connected to battery negative.

Select a location for the switch panel that is convenient to

the toilet user and will also allow access to run the wires

from the switch panel to both the toilet’s waste pump motor

and the PAR-MAX pump as well as from the electrical

power source to the switch panel. To install the switch

panel, drill two 1-3/4" (45 mm) diameter holes (slightly over-

lapping) through the selected switch mounting surface per

the attached template. Ensure the template is oriented cor-

rectly because it is not symmetrical. Also, drill four appropri-

ate sized holes for the fasteners selected to secure the

switch panel to its mounting surface.

R

E

D

BROWN YELLOW

BROWN

YELLOW

RE

D

RED

RE

D

BR

OW

N

YELL

OW

UP

1-3/4" (45 mm) DIA

1-3/4" (45 mm) DIA

TEMPLATE

WIRING DIAGRAM

To Positive

To Waste Pump

Positive (Orange)

Motor Lead

To PAR-MAX Pump

Positive (Orange)

Motor Lead

Page 3

ELECTRICAL SPECIFICATIONS

AMP

FUSE

WIRE SIZE PER FEET OF RUN*

VOLTAGE

DRAW

SIZE

0'-10' (0 M-3 M)

10'-15' (3 M-4,6 M)

15'-25' (4,6 M-7,6 M)

25'-40' (7,6 M-12,2 M )

40'-60'(12,2 M-18,3 M)

12 Vdc

10

25

#16 (1,5 mm2)

#14 (2,5 mm2)

#12 (4 mm2)

#10 (6 mm2)

#8 (10 mm2)

24 Vdc

5

15

#16 (1,5 mm2)

#16 (1,5 mm2)

#16 (1,5 mm2)

#14 (2,5 mm2)

#12 (4 mm2)

* Length of run is total distance from power source to product and back to ground.