JA-82K control panel installation manual

- 5 -

MKH51102

3.7

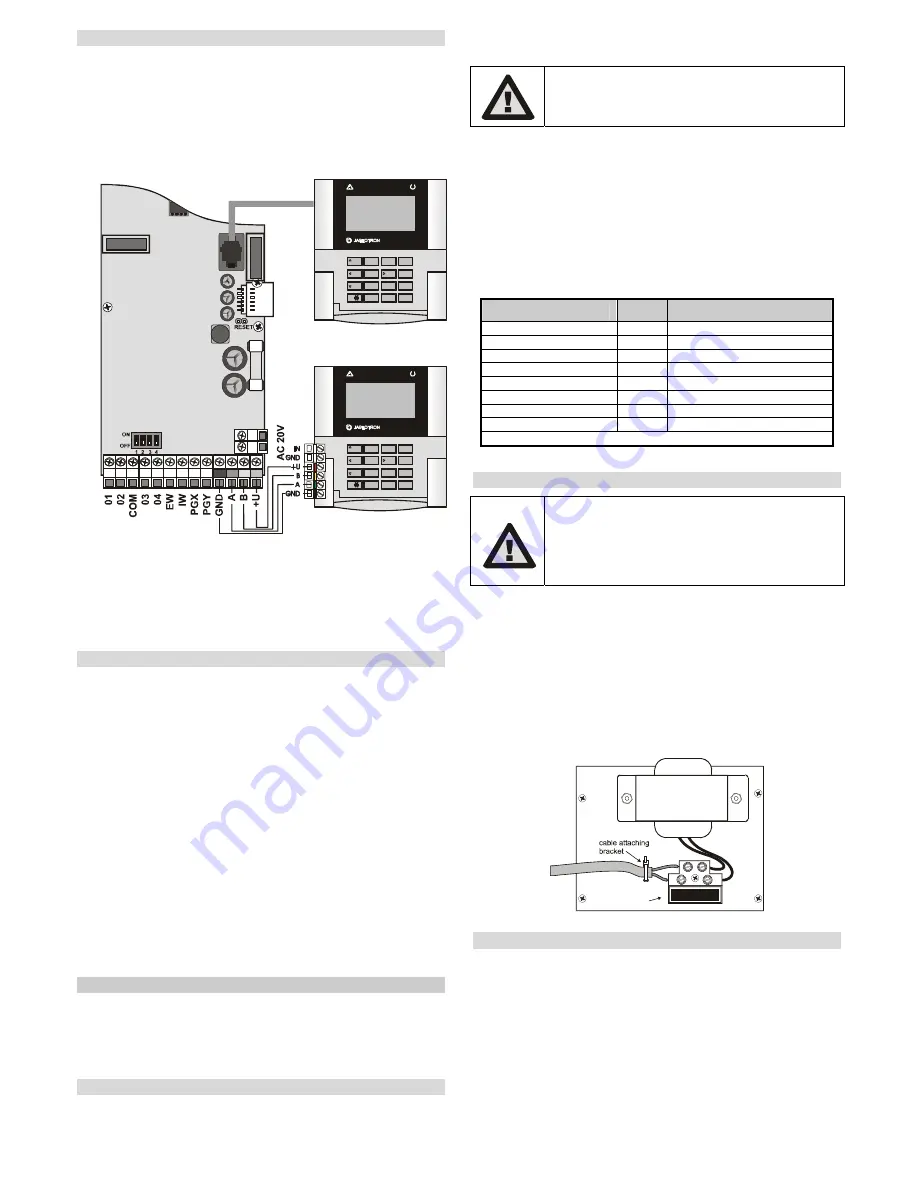

Wired keypad connection

The control panel can be operated and programmed by a JA-80E hard-

wired keypad. A screened four-cord flat cable connecting the corresponding

terminals should be used for permanent connection between the keypad and

the control panel (see fig. 7.)

The keypad can also be connected to a bus connector on the control

panel box using a flat cable (max 10 metres) with RJ connectors for the

purpose of servicing or system debugging.

1

2

3

ABC

4

5

6

A

7

8

9

ON

0

#

B

?

OFF

ESC

A

B

C

OASiS

1

2

3

ABC

4

5

6

A

7

8

9

ON

0

#

B

?

OFF

ESC

A

B

C

OASiS

Control and programming

keypad JA-81E

Modular connection

cable

fig. 7 Wired keypad connection

Note:

When you use the INP keypad hard-wired input to connect the door detector,

its reaction is always delayed (it triggers an entry delay) and it is assigned to

section C.

We recommend having only a single JA-80E hard-wired keypad in the

system.

3.8

Control panel resetting

If you need to set the factory-default settings in the control panel, perform the

following:

1. Disconnect the back-up battery and the mains (using the terminal

board fuse),

2.

Connect the RESET link

and leave it connected,

3.

Connect

the back-up battery and the

mains

,

4.

Wait

until the green LED starts flashing and then

disconnect the

RESET link.

If you need to reset the control panel with preset parameters according to EN

50131-3 (see 6.48) follow these next steps:

1. Disconnect the back-up battery and the mains (using the terminal

board fuse),

2.

Connect the RESET link

and leave it connected,

3.

Connect

the back-up battery and the

mains

,

4.

Wait

until the green LED starts flashing and

key in the sequence

8080

an finally

disconnect the RESET link.

Note:

After a RESET, all wireless devices and access cards are erased from the

control panel as well as user codes.

The Master code changes to 1234, and the service code to 8080.

If resetting is disabled (see 6.8)

it is impossible to reset the control panel.

4

Control panel power supply

Once the control panel is assembled and all modules are in place, you can

proceed with putting the control panel into operation. We recommend

switching the control panel on without any wired detectors connected, using

only the wired keypad (if it is used in the system) for the first time. Only then

should you continue connecting the detectors. Beware of short circuits – it is

strongly recommended to switch off the power when working.

4.1

Backup battery connection

It is possible to use a 12V gel cell backup battery, with a capacity of up to 2.4

Ah in the control panel. The EN 50131-1 standard requires a 12-hour minimum

backup time in case of a power grid failure. For the standby consumption of all

system devices, see fig. 8.

ATTENTION – the backup battery is sold

charged, avoid shorting out its terminals!

The average backup battery lifetime is up to 5 years after which it must be

replaced

. Checking its capacity during regular maintenance is

recommended.

The control panel automatically recharges the backup battery

and monitors its condition.

When the system runs only on the backup

battery, the battery status is monitored and a technical alarm is triggered

before its complete depletion. The backup battery is then disconnected.

Once the

power supply has been restored, the battery reconnects and is

recharged

.

Ensure that the battery is correctly connected (Polarity: RED = po,

BLACK = negative -).

fig. 8 power consumption of individual components

4.2 Power

supply

connection

Only a person with corresponding electro-

technical qualification can connect the power

supply.

The control panel power supply is double-

insulated (safety class 2) and does not

incorporate a protective grounding wire.

The control-panel power cable should only be installed by a person holding

a sufficient electro-technical qualification.

The control panel power supply is double-insulated (protection class II) and

does not incorporate a protective earth wire.

•

A double-insulated power cable should be used with a minimum cross-

sectional area of 0.75 to 1.5 mm

2

. The power cable should be connected

to a switched mains supply fused to 10 Amps.

•

In the control panel, connect the cable to the power terminals equipped

with a fuse of type T200mA/250V.

•

Fix the cable firmly to the cable holder

in the control panel making sure

that the wire ends are properly secured and connected in the terminals.

Mains fuse

T 200 mA

4.3

Powering-up the control panel for the first time

13. First check all the wiring, and if a GSM communicator is installed, insert its SIM

card (PIN code disabled).

14. Check the backup battery connection

15. Switch the power supply on – a green LED starts flashing on the control panel

board.

16. If a hard-wired keypad is connected it indicates “Service” mode

17. The control panel can also be set up via the interface using OLink software – (A

virtual keypad can be used in OLink to indicate system status).

18. If you have neither the wired keypad, nor OLink, enrol a wireless keypad by the

following means:

a) have an opened keypad and its battery ready,

b) check that the green LED in the control panel is flashing,

c) short the RESET link in the control panel for 1 second (enrollment mode

opens),

device

mA

note

JA-82K control panel

30

without a communicator

JA-82R module

20

JA-82C module

15

JA-80E keypad

30

JA-80H (N) keypad

60

including WJ-80 interface

JA-80Y communicator

35

JA-80V communicator

30

JA-80X communicator

15

Wireless devices are not powered from the control panel