8670-5WB Manual – 10/2006

22

TROUBLESHOOTING

! IMPORTANT!

TROUBLESHOOTING SHOULD BE DONE BY A QUALIFIED ELECTRICIAN OR TECHNICIAN WITH POWER DISCONNECTED

WHENEVER POSSIBLE. PROCEDURES MARKED !CAUTION! REQUIRE THAT THE POWER BE ON AND MAY INVOLVE DANGEROUS

VOLTAGES.

Problem

Possible Cause

Solution

No power to machine

Check circuit breaker for machine. Reset if needed.

!CAUTION!

Inadequate power to machine

Verify proper service hookups. Air machine should have a

dedicated

120V, 20A, 60Hz

single phase service. Improper electrical service can lead to erratic behavior and may

damage components.

Improper timer setup

Verify timer is set properly using timer setup charts on pages 11-15.

Loose/Missing/Damaged wire

Verify integrity of wires. If possible, trace continuity between key components

(compressor, timer, coin mech, solenoid).

Check key components to isolate failure:

Timer:

Verify proper input voltage. Activate timer. If no output voltage is present

when timer should be active, replace timer.

Water solenoid:

Check voltage across the solenoid. Replace solenoid if proper

voltage (120VAC) is present and solenoid doesn't engage. If solenoid is stuck doesn't

disengage when voltage not present, disassemble and clean solenoid.

Coin mech:

Remove the wires leading to the timer from the coin mech and tap them

together one time for each coin necessary to start the timer. If machine starts, replace

the coin mech.

Remote Starter:

Test transmitter batteries and replace if needed. Remove receiver

cover and verify proper voltage across terminals 1 and 3 (24VAC). If proper voltage is

present and transmitter batteries are good, follow instructions to program transmitter

and receiver. If remote starter still will not function correctly, replace with new remote

system.

Compressor: !CAUTION - DANGEROUS VOLTAGE LEVELS PRESENT -

QUALIFIED ELECTRICIANS ONLY!

Bleed remaining air from line and verify proper

voltage (120VAC) across compressor leads. If proper votage is present and

compressor will not start, replace compressor. If compressor starts with no pressure in

air line but will not start when pressure is present, replace unloader valve.

Timer giving

inaccurate time

Improper timer setup

Reset the timer according to instructions on pages 11-15.

Loose wiring

Inspect wiring from coin mech and remote start to timer to verify proper connection.

!CAUTION!

Damaged timer/Coin mech

Isolate timers from coin mech and remote start. If timer continues to run after the

maximum possible timer setting, replace timer. If unit times out and turns off, coin

mech or remote start may need to be replaced.

Unit runs

continuously and will

not shut off

!CAUTION!

Component failure

Unit will not start

Summary of Contents for 8670-5WB

Page 1: ......

Page 7: ...8670 5WB Manual 10 2006 7 Figure 1 Installation footprint for 6025 hose reel base ...

Page 8: ...8670 5WB Manual 10 2006 8 Figure 2 Mounting and routing detail ...

Page 9: ...8670 5WB Manual 10 2006 9 Figure 3 Electrical installation detail ...

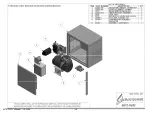

Page 10: ...8670 5WB Manual 10 2006 10 Figure 4 Cabinet and hose reel base dimensions ...

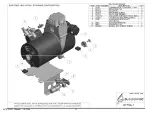

Page 18: ...8670 5WB Manual 10 2006 18 ...

Page 19: ...8670 5WB Manual 10 2006 19 ...

Page 20: ...8670 5WB Manual 10 2006 20 ...

Page 21: ......