M

AINTENANCE

turn clockwise in quarter turns - the limit value

is increased,

turn counter-clockwise in quarter turns - the

limit value is reduced,

5. Secure threaded pins with the lock nuts. Do

not turn the threaded pins any more as the

setting will be altered.

6. Check the limit value for correct setting.

7. Install the gearbox cover.

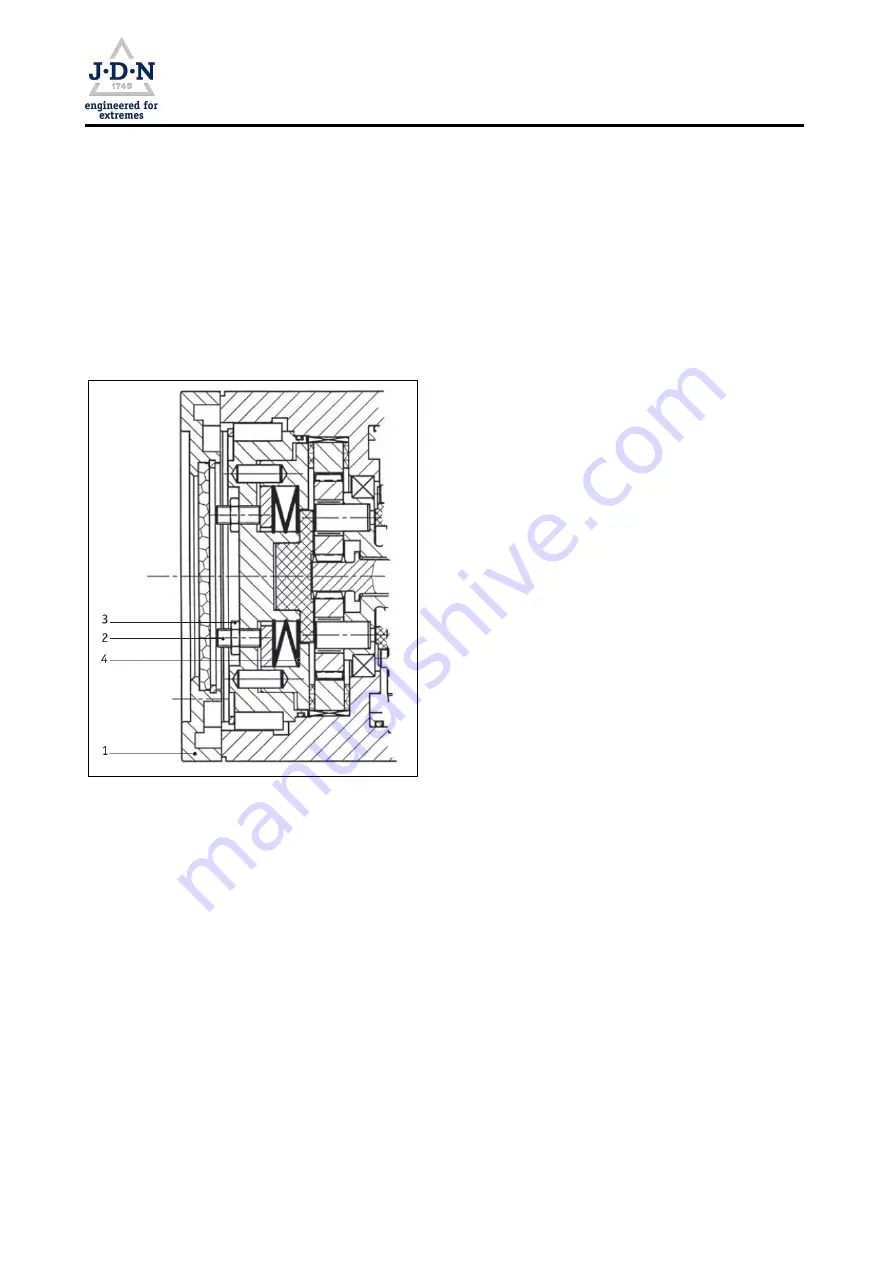

Figure 14: Adjusting overload protection

Re-adjust the overload protection

The adjust-

ment method described here is based on the at-

tachment of test loads (

,

→

Figure 14). The over-

load protection is located on the gearbox.

1. Unload the hoist.

2. Detach the gearbox cover

(1)

vfrom the gear-

box in order to gain access to the threaded

pins

(2)

with lock nuts

(3)

located behind it.

3. Loosen the lock nuts. Screw out the threaded

pins until the disc springs

(4)

are completely

free of pre-tension.

4. Then loosely screw in the threaded pins by

hand to the stop. Unscrew the lock nuts suffi-

ciently far back beforehand.

5. The limit value for reaching at least 110% of

the load capacity is set at approximately 2

turns. Screw in the three threaded pins suc-

cessively in small steps by approximately

1/2 turn. With this pre-adjustment after re-

assembly, first let the safety clutch take effect

for approx. 5 seconds without the load (load

hook on the upper end position with the motor

running). Then let the load hook run for ap-

prox. 10 seconds without a load so that the

outlet air cools the clutch down.

6. Secure threaded pins with the lock nuts. Hold

the threaded pins tightly in the process.

7. Check the limit value for correct setting, cor-

rect if necessary.

8. Install the gearbox cover.

9. The adjusting and inspecting result arrived at

by qualified personnel must be entered in the

inspection log.

Doc.-No.: VA049318-20-OM-EN-0319-64-6

Page

53

of 64