powered by air !

M A I N T E N A NC E

Page 37

Should the wear limit be reached prematurely, the

actual compressed air pressure must be checked with

the device switched on (the brake drags in the event

of insufficient pressure).

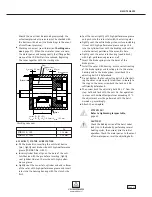

Checking vane wear (see illustration

Checking vane

wear,

page 37). When the air motor vanes are worn,

the motor power and consequently the lifting perfor-

mance of the JDN Air Hoist are reduced. Replacing

the vanes together with the starting aids.

A S S E M B LY / M O T O R L U B R I C AT I O N

Fit the brake disc, inserting the anti-twist device

(pin), lightly coat brake side with high-performance

grease (JDN ART. No. 11901).

Insert cylinder liner, align on the bore of the anti-

twist device with the pin before inserting, lightly

coat cylinder liner on the inside with high-perfor-

mance grease.

Lightly coat the vane slots, cylinder and end surfaces

of the rotor with high-performance grease and insert

rotor into the housing bearing with the clutch side

first.

Coat the vanes lightly with high-performance grease

and push into the rotor slots with the starting aids.

Lightly coat the entire brake piston surface including

its seal with high-performance grease and push it

into the cylinder liner with the braking surface first;

note the correct position of the eccentric bore.

Lightly coat the outer rotor bearing (needle bush)

with high-performance grease as well.

Insert the brake springs into the bores of the

brake piston.

Install the cover with bearing, ensure correct seating

of the brake springs and locating pins to the motor

housing and to the brake piston, screw back the

adjusting bolts

13

beforehand.

Do not tighten the four adjusting bolts

13

after bolt-

ing the cover in place; only screw them in loosely to

the stop in the cover, screw back the lock nuts

14

sufficiently beforehand.

Then screw back the adjusting bolts

13

45° from the

stop, hold and lock with the nuts

14

. For operation

in areas with ambient temperatures exceeding 30° C,

the adjustment must be performed with the hoist

warmed up accordingly.

Attach the nameplate.

AT T E N T I O N !

Refer to tightening torques table,

page 45.

C AU T I O N !

Check the braking action of the hoist under

load (run in the brake by performing several

hoisting cycles, then assess) prior to initial

operation. Check the motor power. In the event

of low motor power, reset the adjusting bolts.

Checking vane wear

Vane

Rotor

Cylinder liner

Brake piston

V2 max. = 0.2 mm

•

•

•

Brake disc

•

V1 max. = 0.2 mm

R

•

Lmax = R – (V1 + V2)

Lmin = R – (V1 + V2) – 0.3 mm = Lmax – 0.3 mm

L

L h

L

h

MINI 125 / 250

≥

14 mm

MINI 500 / 1000

≥

19 mm

Summary of Contents for JDN mini 1000

Page 47: ...powered by air NOTES Page 47 ...