5.

Headgear adjustments

Because the shapes of man's heads vary from person to person. The work positions

and the observing angles are different. Operator may adjust the headband in 5

parameters:

1. Select eye level by Headband adjusting buttons (23).

2. Select view angle by Segmental positioning plate (20).

3. Adjust head size perimeter by pushing and turning the Headband tightness adjust-

ing knob (16).

4. Select eyes distance from ADF by adjusting Headgear screws to 1 of the 5 slots on

the Headgear slider (15). Make sure both sides are equally positioned for proper

vision.

5. Select the height of the headgear by adjusting the Block washers(14,19) up or

down on the Block washer adjustment(17).

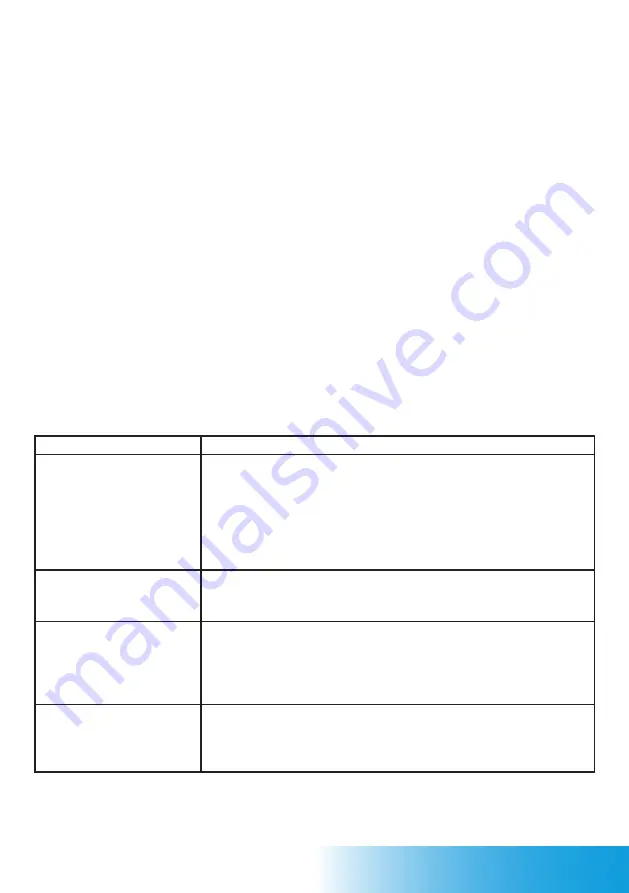

Malfunctions

Solutions

The ADF does not

darken when welding.

-Stop welding or cutting immediately.

-Make sure the sensors are facing the arc and no obstruc-

tions.

-Check the mode that is on WELD not GRIND.

-Review sensitivity recommendations and adjust sensitivity

if possible.

-Replace the battery if necessary.

The ADF stays dark after

welding or there is no

arc present.

-Adjust the sensitivity to the lower level (level 1).

-If the welding place is extremely bright, it is recommend-

ed to reduce the surrounding light level.

The ADF switching dur-

ing the welding.

-Increase the sensitivity if possible.

-Make sure the sensors are facing the arc and no obstruc-

tions.

-Increase Delay 0.1 − 0.3 second may also reduce switch-

ing.

Inconsistent shade

number on the corner

of ADF.

-It is a natural feature and will not be dangerous for the

eyes.

-In order to get a maximum comfort, try to keep an view

angle at around 90°.

6.

Troubleshooting

EN-7