- 26 -

2. Maintenance & Inspection

■ Daily inspection

Pay attention to the following items during operation. Stop operation on sensing danger and solve problems

on the Troubleshooting section.

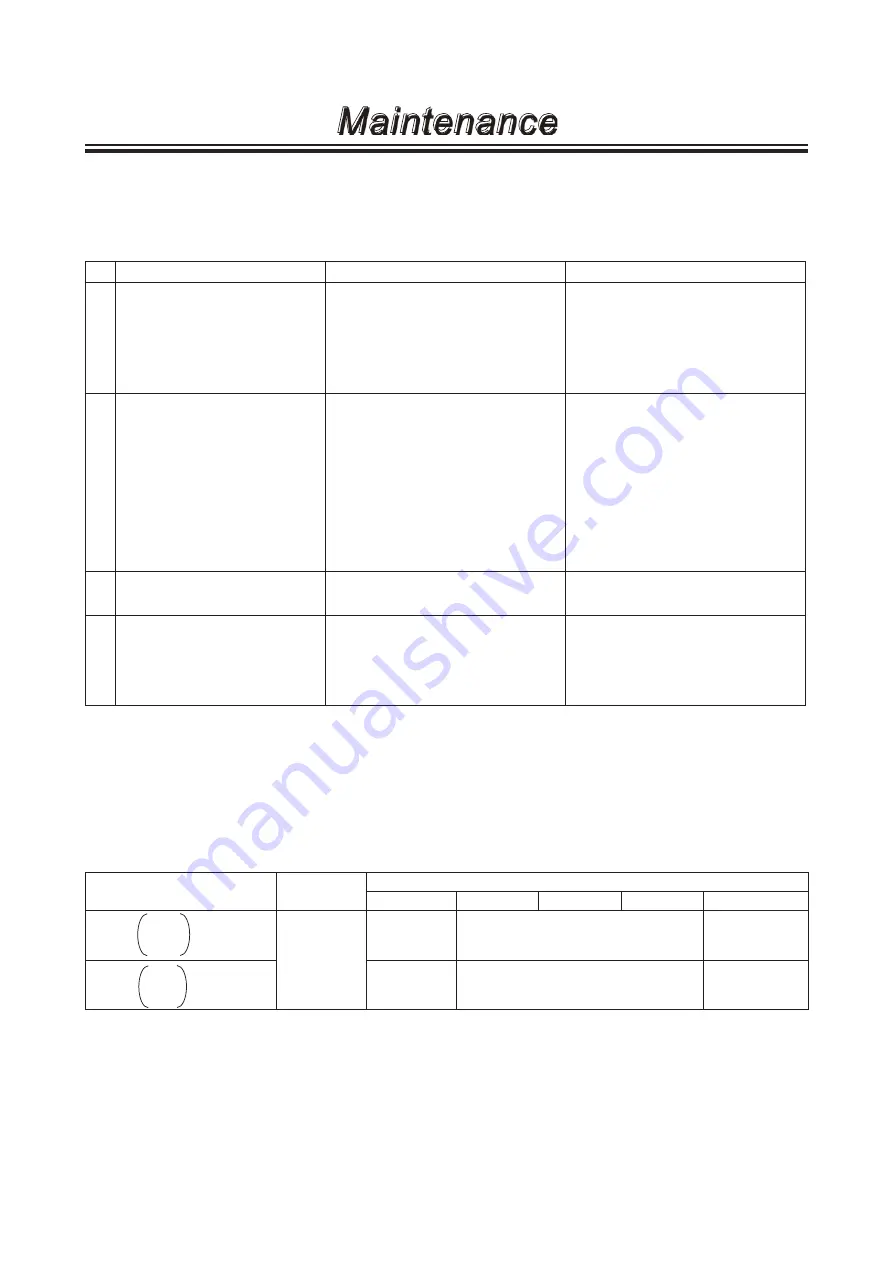

No.

States

Points to be checked

How to check

1 Operation

● If air is pumped.

● If the suction and discharge

pressure are normal.

● If power voltage and current are

normal.

● Air flow meter, pressure gauge

or visual inspection

● See a spec label.

2 Starting

● If abnormal noise or vibration

occurs. They are signs of abnor-

mal operation.

● A baseplate, if installed, under

the pump may resonate with

operation, making a mechanical

noise. Insert a rubber cushion as

necessary to reduce resonance.

● Visual or audio inspection

● Visual or audio inspection

3

Air leak or ingress from pump

head joints and a suction line

● Tighten a loose joint.

● Air flow meter, pressure gauge

or visual inspection

4

Pump and motor surface tem-

perature rise

● Pump and motor surface tem-

perature should be at or below a

total of ambient temperature plus

50°C.

● Thermometer

■ Wear parts

If pump performance has remarkably reduced, replace diaphragms and valves with new ones.

Wear part duration varies with the pressure, temperature and characteristics of liquid.

The estimated life below is calculated based on continuous operation with clean water at ambient tempera-

ture (Room temperature range is 0-40°C.).

Model

Load range

Estimated life

Valve

Diaphragm

Seat

Gasket

Filter (Option)

450

APN- P450 NAT-NATX

S450

All range

8000

4000

4000

450

APN- P450 NST-NSTX

S450

8000

4000

-

Maintenance

Summary of Contents for APN-450

Page 17: ... 15 Installation 1 Before installation 16 2 Installation Tubing Electrical wiring 19 ...

Page 24: ... 22 Operation 1 Before operation 23 2 Pump operation 23 ...

Page 26: ... 24 Maintenance 1 Troubleshooting 25 2 Maintenance Inspection 26 3 Wear part replacement 27 ...

Page 34: ... 32 ...

Page 35: ... 33 ...