V

10/04

36

•

Cleaning and repair

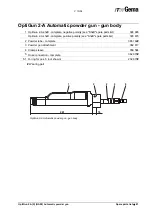

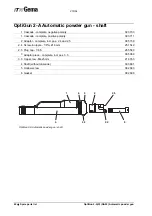

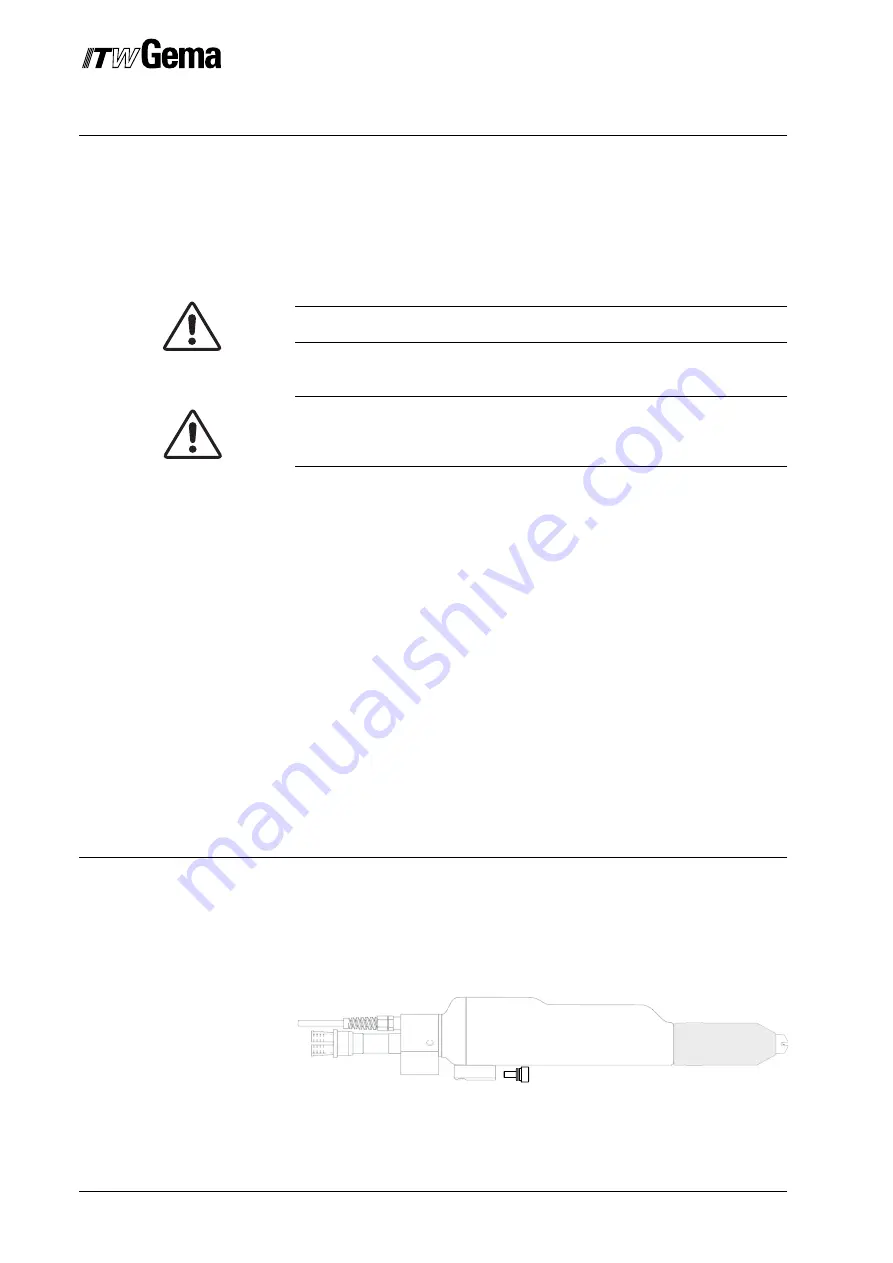

OptiGun 2-A(X) (GA02) Automatic powder gun

Cleaning the spray nozzles

Daily or after each shift

1. Blow off the spray nozzles externally with compressed air

Solvents or other fluidities can also be used for cleaning the spray noz-

zles.

Clean the spray nozzles only with a solvent soaked cloth, never im-

merse the parts in solvent!

2. Check the seating of the spray nozzles

It is to be noted, that the sleeve nut is always tightened well. If the

spray nozzle is only fitted loosely, the danger exists that the high

voltage of the gun can jump over to the spray nozzle, which can in-

evitably lead to damage to the powder gun!

Weekly

Remove the spray nozzles and clean inside with compressed air. If pow-

der sinterings should have formed, these are to be removed.

Monthly

Check the spray nozzles for abrasion. The flat jet nozzle is to be

changed, if:

-

The spray pattern is no longer a regular oval

-

Deeper grooves are in the nozzle slot, or even the wall thick-

ness is not longer visible

-

The wedge of the electrode holder is worn down

-

On nozzles with deflector, the wedge of the electrode holder

can be worn down. In this case, the electrode holder is to be

replaced!

Cleaning the SuperCorona

In the case of a disassembly of the SuperCorona ring, the SuperCorona

connection must be cleaned and closed with the corresponding plug cap

(order no. 1001 037). This prevents powder deposits and contact prob-

lems on SuperCorona connection.

SuperCorona plug cap