V

10/04

OptiGun 2-A(X) (GA02) Automatic powder gun

Structure and function

•

17

Spray nozzles

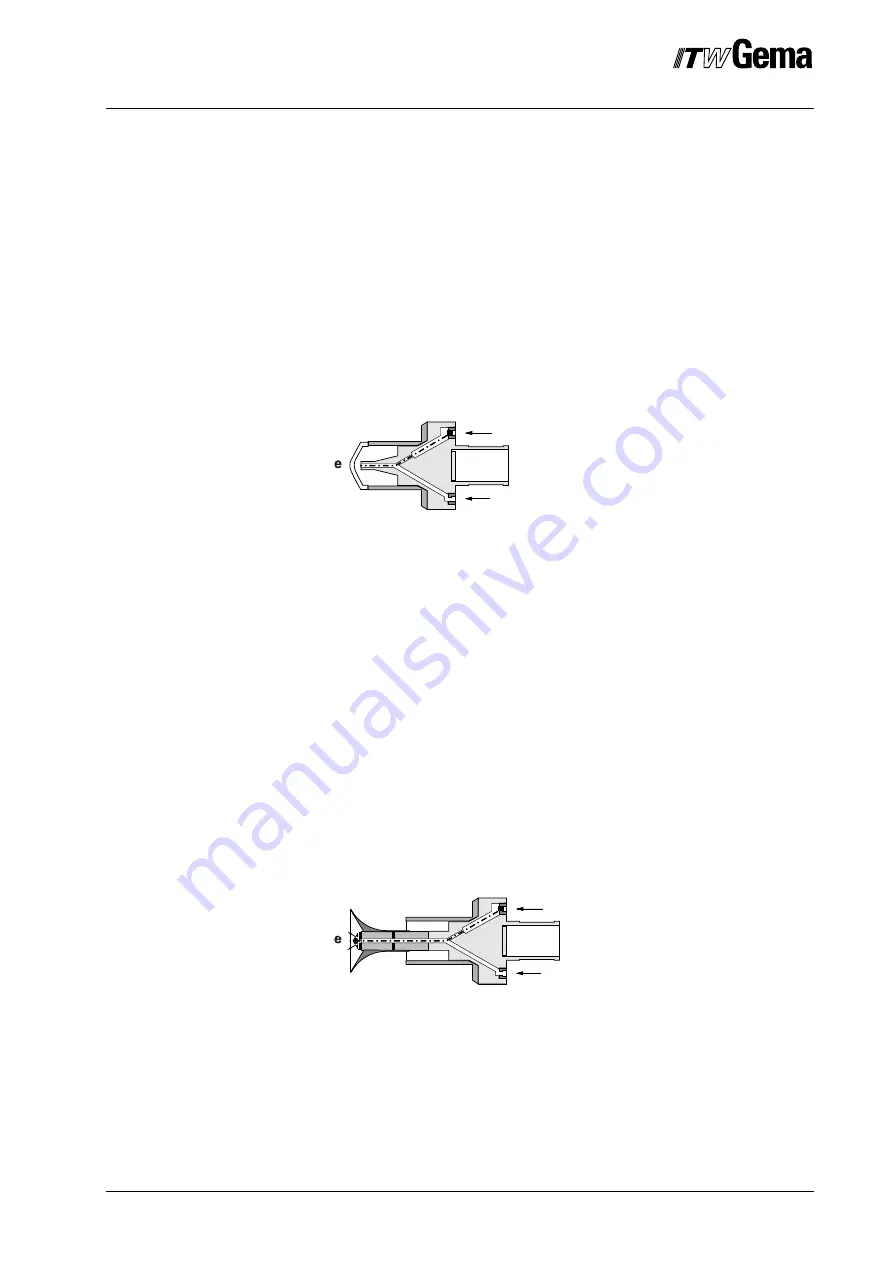

Flat jet nozzle with vented central electrode

The vented flat jet nozzle serves for the atomizing and charging of the

powder. The powder cloud obtains an oval spray pattern by the slot-

shaped opening. The powder is charged by the central electrode. The

high voltage, which is created in the gun cascade, is conducted through

the black contact ring of the nozzle holder to the central electrode.

In order to prevent a powder sintering on the electrode, this is rinsed with

compressed air during spraying procedure. Therefore, the rinsing air is

fed through the small hole in the black contact ring of the nozzle holder

into the electrode attachment. The rinsing air adjustment on the control

module is explained in the corresponding operating manual.

Flat jet nozzle with vented central electrode

Round jet nozzle with vented deflector and

vented central electrode

The vented deflector is used to give to the powder stream emerging from

the gun the form of a powder cloud. The powder is charged by the central

electrode. The high voltage, which is created in the gun cascade, is con-

ducted through the black contact ring of the nozzle holder to the central

electrode.

Since powder can accumulate on the rear side of the deflector, this must

be rinsed with compressed air. The rinsing air is fed through the small

hole in the black contact ring of the nozzle holder into the electrode at-

tachment, and is driven in such a way, that it flows over the surface of the

deflector rear side. The rinsing air strength depends on the powder and

its sintering ability. The rinsing air adjustment on the control module is

explained in the corresponding operating manual.

Round jet nozzle with vented deflector and vented central electrode

High voltage

Rinsing air

High voltage

Rinsing air