For more information, see Fastener torque table for valve body to topworks in this manual.

4. Make multiple crisscross passes to build up torque to the final table value. Make additional crisscross

passes using final table values to evenly tighten each fastener to within 5% of torque value.

5. Retighten the bonnet fasteners as noted above at ambient conditions after the system has cycled

through operating pressure and temperature.

6. Monitor the valve for leakage:

If leakage ...

Then ...

Occurs at the body/bonnet

flange sealing area

Depressurize the system and retighten the bonnet fasteners as

noted above.

Continues

Depressurize the system and retighten the bonnet fasteners as

noted above. (maximum 3rd re-torque)

Continues

Replace the valve diaphragm.

For more information, see Replace the valve diaphragm in this manual.

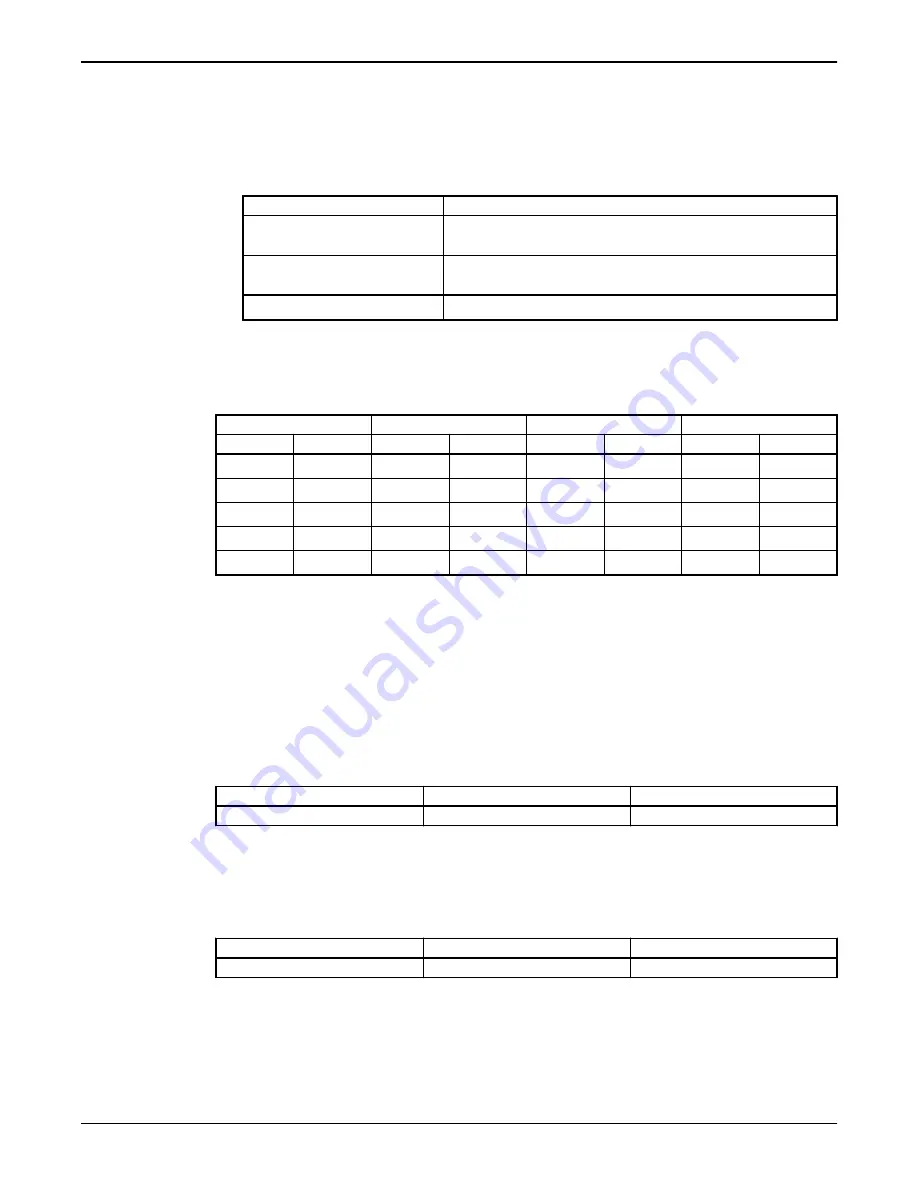

Fastener torque table for valve body to topworks

Values given are for lubricated fasteners.

Valve size

Bolt size

PTFE diaphragm

Elastomer diaphragm

Inch

DN

Imperial

Metric

in-lb

N-m

in-lb

N-m

0.50

15

1/4"

M6

25-60

2.8-6.8

20-40

2.3-4.5

0.75

20

1/4"

M6

50-65

5.7-9.1

20-50

2.3-5.7

1.00

25

5/16"

M8

65-90

7.4-11.3

45-70

5.1-7.9

1.50

40

3/8"

M10

200-225

23-25

75-130

8.5-14.7

2.00

50

7/16"

M12

225-275

25-31

100-180

11-20

Guidelines

• Minimum values given will provide a longer diaphragm cycle life for valves in non-autoclave and low

thermal cycle conditions.

• Maximum values given may be necessary for autoclave conditions and for high thermal cycle

conditions.

• Torques should be applied at near ambient conditions (less than 100ºF (38ºC)).

Actuator operating pressure

Maximum permitted air supply pressure

psig

bar

kPA

90

6.2

620

Actuator pressure rating

The actuator will withstand pressures well in excess of the rated pressure without risk of bursting.

Maintaining operating pressure at or below the pressure rating will ensure optimum life of the operating

components, such as the actuator diaphragm. However, operation at pressures up to 100 psig (6.9 bar), for

limited periods of time, will not noticeably affect the life of these components.

psig

bar

kPA

90

6.2

620

Set the adjustable opening stop

These instructions are for series 3, 5, 8, 16 actuators.

1. Remove the switch package, if present.

2. Using air pressure and a bleed type regulator, open the valve to the desired position.

Installation

Advantage

®

Actuator 2.0 Installation and Operation Manual

13