SCREW AIR COMPRESSOR OPERATOR’S MANUAL TM356-10270

English

24

Code 1641003212 - Edition 10/2020

NOTE ON LUBRICANTS

When delivered the machine is filled with oil;

In normal conditions of use, these lubricants have proved to be able to withstand use for as many as

4.000 hours.

However, due to the external polluting agents that get into the compressor with the air suction,

it is advisable to change the oil at more frequent intervals, as indicated on the routine maintenance chart.

If the compressor is being used at high temperatures (continuous operation above 90 °C) or in

particularly severe conditions, we advise changing the oil at shorter intervals than those recommended

in the maintenance chart.

DO NOT TOP UP WITH DIFFERENT OILS

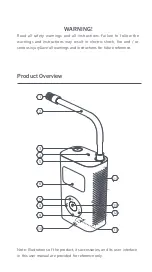

15.8 REPLACING THE OIL SEPERATOR ELEMENT AND OIL FILTER

BEFORE CARRYING OUT ANY MAINTENANCE THE MACHINE MUST BE STOPPED, CUT

OFF THE MACHINE FROM THE ELECTRICAL MAINS AND FROM THE COMPRESSED AIR

DISTRIBUTION CIRCUIT, CHECK THAT THE MACHINE IS NOT UNDER PRESSURE.

Before proceeding with the replacement of the de-oiler filter or the oil filter check that there is no

pressure in the machine: check the pressure gauge Ref. 1,2 Fig. 19.

- Lubricate the filter seals with a little oil before fitting.

- Tightening must be done by hand.

FIG. 19

1

2

24

www.itmtools.com.au