Green Heating Technology

19

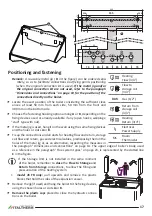

Piping between the boiler and the storage unit

Link the connection on the boiler identified by

MB

(flow to storage) to the

MB

connection of the Storage

Unit, and the

RB

(return from storage) connection of the boiler to the

RB

connection of the Storage Unit.

Swapping the flow and return connections could lead to malfunctions.

Warning:

If a recirculation pump is installed, install a check valve.

Heating system filling and pressuring

Once all system connections have been carried out, pro-

ceed with system filling. This operation should be made

with care, respecting the following steps:

f

Open the radiators venting devices;

f

Check that the plug of the automatic air vent, incorpo-

rated in the boiler circulator, is unscrewed: if not, un-

screw it and leave it unscrewed, even afterwards, for

normal operation;

f

Locate the system filling device, foreseen externally to

the boiler, and proceed depending on its type:

• filling from aqueduct: open it and let water flow in

the system

• filling with anti-freeze solution: pump in the solution and pressurize the system.

f

Check the correct functioning of automatic venting devices, eventually installed on the heating sys-

tem and/or on the storage coil circuit;

f

Close the radiators venting devices as soon as water or anti-freeze solution flows out of them;

f

If the storage coil or the relevant circuit were equipped with manual venting valves, use them to

purge the residual air from them;

f

Make sure, by reading the pressure gauge

1

, that the pressure reaches the optimal value of

1.0 bar

(max 1.5 bar)

;

f

Close the filling device and bleed each radiator again;

f

Repeat the venting and pressurization operations until the air is completely purged from the system.

DHW storage tank filling

f

Fill the DHW storage tank (on storage unit):

• open one of the hot water taps in the DHW system;

• gradually open the hand valve installed on the cold water inlet of the storage unit;

• when only water flows out of the tap, close it.

00337_0

0

3

4

1