25

USE AND MAINTENANCE MANUAL

MILLENNIUM MY2019

EN

428001137037

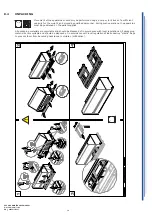

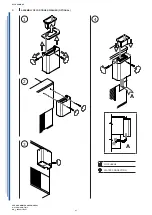

11.6 OPERATOR SIDE

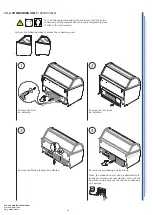

OPENING / CLOSING

MANUAL SELF-WINDING BLIND

(STANDARD)

ATTENTION

Open and close the blind manually without forcing and ensure complete / correct closure;

incomplete / correct closure negatively affects the performance of the equipment and can result in the

excessive accumulation of ice on the internal walls.

SLIDING

(VARIANT)

ATTENTION

Open and close the slides manually without forcing and close them, making sure they are completely closed;

incorrect closure negatively affects the performance of the equipment and can result in the excessive

accumulation of ice on the internal walls.

Summary of Contents for MILLENNIUM MY2019

Page 38: ......