It is important that the boiler is initially

filled and started for the first time using

the method shown in 2.3.3 section e).

This procedure should also be used

when refilling after draining a boiler.

The boiler must be installed in a fixed

location and only by specialized and

qualified person in compliance with all

instructions contained in this manual.

The installation of this boiler must

be in accordance with the relevant

requirements of the current Gas Safety

(installation and use), the local building

regulations, and and I.E.E. wiring

regulations.

Detailled recommendations

for air supply are given in BS5440:2.

The following notes are for general

guidance: it is not necessary to have a

purpose provided air vent in the room

or compartment in which the appliance

is installed.

2.1 ANTI-FREEZE

FUNCTION

The boilers are equipped with anti-freeze

function which activates the pump and

the burner when the temperature of the

water contained inside the appliance

drops to below value PAR 10. The anti-

freeze function can only operate if:

– the boiler is correctly connected to

the gas and electricity supply circuits;

– the boiler is switched on;

– the boiler ignition is not locked out;

– the essential components of the boiler

are all in working order.

In these conditions the boiler is protected

against frost down to an environmental

temperature of -5°C.

ATTENTION: In the case of installation

in a place where the temperature drops

below 0°C, the connection pipes must

be protected.

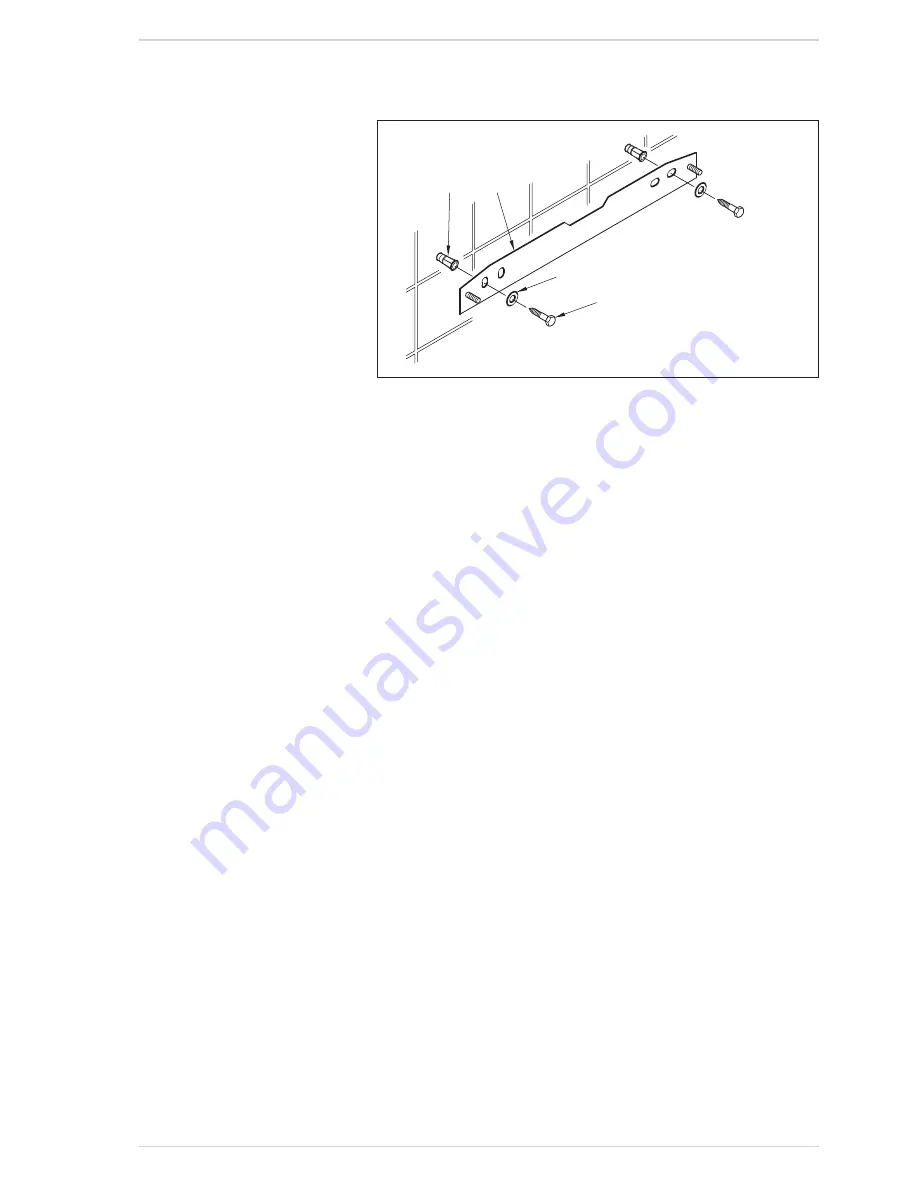

2.2

FIXING THE WALL

MOUNTING BRACKET (fig. 4)

– Mark the position of the two wall

mounting bracket fixing holes and the

flue/air duct hole on the appropriate

wall(s).

– Drill the two fixing holes using a 10

mm masonry drill and fit the plastic

plugs provided.

– Accurately measure the wall thickness,

and note this dimension for later use.

– Secure the wall mounting bracket in

position using the screws provided.

Ensure that it is the correct way up,

as indicated in fig. 4.

2.3

CONNECTING UP SYSTEM

Before connecting the boiler it is

recommended that the system be

flushed in accordance to BS 7593, to

eliminate any foreign bodies that may be

detrimental to the operating efficiency

of the appliance. When connecting up

the boiler the clearances in fig 1 should

be respected.

The boiler is supplied with a valve pack

part number 5184817A. The boiler can be

filled and pressure tested prior to any

electrical supply being connected with

the use of the analogue pressure gauge.

A safety valve set at 3 bar is fitted to the

appliance, the discharge pipe provided

should be extended to terminate safely

away from the appliance and where

a discharge would not cause damage

to persons or property but would be

detected. The pipe should be a minimum

of 15 mm Ø and should be able to

withstand boiling water, any should

avoid sharp corners or upward pipe

runs where water may be retained.

Gas Connection

The gas connection must be made

using seamless steel or copper pipe.

Where the piping has to pass through

walls, a suitable insulating sleeve must

be provided. When sizing gas piping,

from the meter to the boiler, take into

account both the volume flow rates

(consumption) in m

3

/h and the relative

density of the gas in question. The

sections of the piping making up the

system must be such as to guarantee

a supply of gas sufficient to cover the

maximum demand, limiting pressure

loss between the gas meter and any

apparatus being used to not greater

than 1.0 mbar for family II gases (natural

gas). An adhesive data badge is sited

inside the front panel; it contains all the

technical data identifying the boiler and

the type of gas for which the boiler is

arranged.

2.3.1 Connection of condensation

water

trap

To ensure safe disposal of the condensate

produced by the flue gases, reference

should be made to BS6798:2009.

The boiler incorporates a condensate

trap which has a seal of 75 mm, therefore

no additional trap is required. The

advised method of connection to the

condensate trap is by using 20 mm

overflow pipe with a socket attached to

cover the condensate trap connection.

The condensate should ideally be

discharged internally into an internal

waste pipe(washing machine/sink

waste) or a soil pipe to avoid the risk

of freezing.

External pipe runs should be avoided, but

if it is necessary, the pipework should be

at least 32mm and protected from the risc

of freezing with a waterproof insulation

and the length kept to a minimum and

not exceeding 3 m. termination should

be into an external gully or purpose

made soakaway.

NOTE: All pipework must have a

continuous fall from the boiler and must

be resistant to corrosion by condensate,

copper or steel is NOT suitable.

It should be noted that the connection

of a condensate pipe to a drain may

be subject to local building control

requirements.

2.3.2 Dealing with condensate

See APPENDIX A for guidance on the

disposal of condensate.

2.3.3 Requirements for sealed water

systems (fig. 5)

The heating system design should be

based on the following information:

a) The available pump head is given in

fig. 14.

b) The burner starts if the system

pressure is sufficient to operate the

pressure switch.

c) The appliance is equipped with an

internal by-pass that operates with

system heads (H) greater than 3

m. The maximum flow through

the by-pass is about 300 l/h. If

thermostatic radiator valves are to

be installed, at least one radiator

should be without a thermostatic

valve (usually the bathroom radiator

or the radiator in the room containing

2 INSTALLATION

10

1

2

3

4

KEY

1 Wall mounting bracket

2 Plastic wall plug (2 Off)

3 Woodscrew (2 Off)

4 Washer (2 Off)

Fig. 4

Summary of Contents for COMFORT 30

Page 3: ......

Page 28: ...28 7 EXPLODED VIEWS...

Page 29: ...29...

Page 45: ...NOTES...

Page 46: ...NOTES...

Page 47: ......

Page 48: ...iqe co uk Trade House BA22 8RT Phone 0800 0152252...