21

the alarm “AL 02”.

Increase the system pressure to

between 1.0 and 1.2 bar (use pressure

gauge, fig 22/a) using the external

filling loop. The boiler will automatically

resume operating.

–

C.H. SENSOR ERROR ALARM 05

When C.H. sensor (SM) is open or

short circuited, the boiler will not

function and the display will show the

alarm “AL 05”.

–

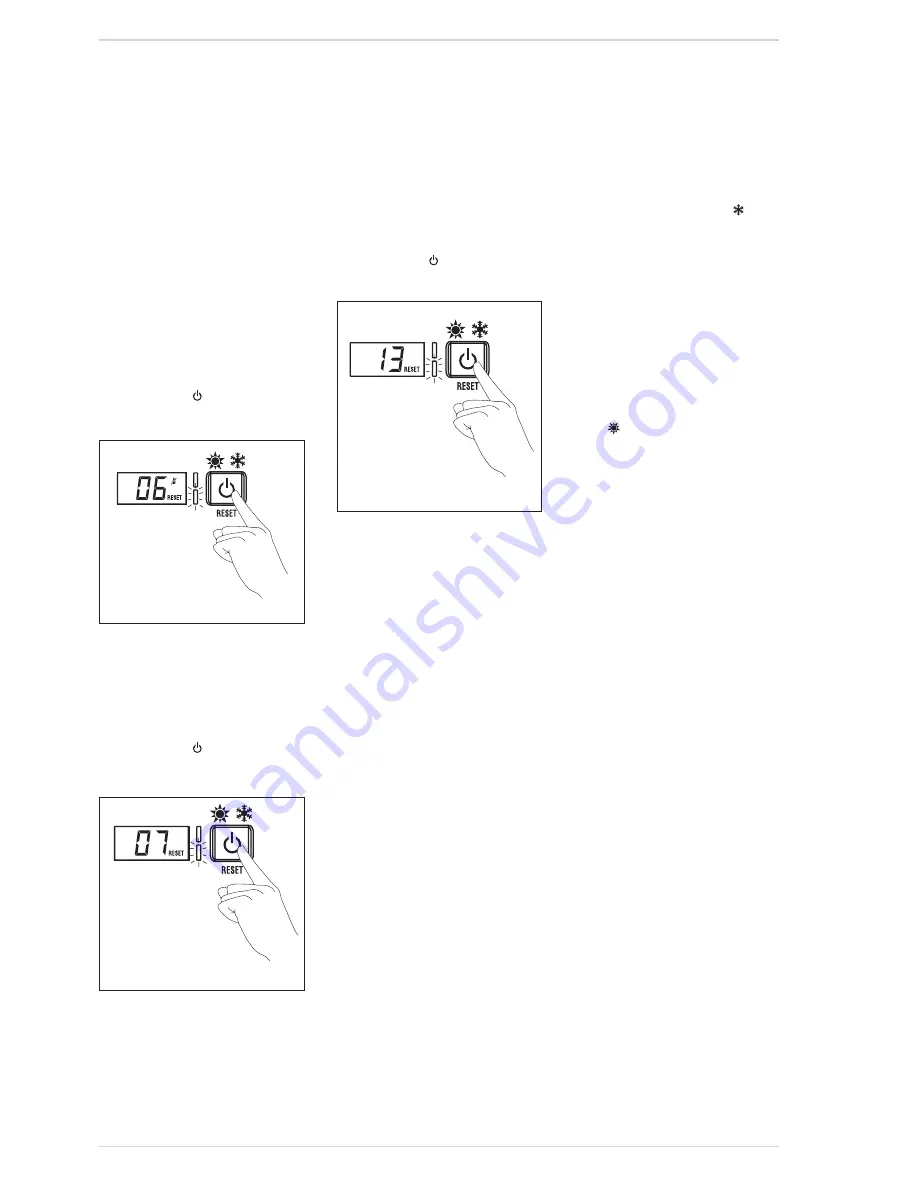

LOCKOUT ALARM 06 (fig. 22/b)

If the flame control has not detected

the presence of the flame after a

complete ignition sequence, or for any

other reason the card cannot “see”

the flame, the boiler will stop and the

display will show the alarm “AL 06”.

Press the key

of the controls to

start up the boiler again.

–

SAFETY THERMOSTAT ERROR

ALARM 07 (fig. 22/c)

Opening of the safety thermostat will

turn off the burner, the display will

show AL07. If the problem persists for

more than one minute, the boiler will

stop and the red LED will turn on.

Press the key

of the controls to

start up the boiler again.

–

FLAME DETECTION ERROR ALARM 08

If a flame is detected when one should

not be present, the boiler will stop and

the display will show “AL 08”

–

D.H.W. SENSOR ERROR ALARM 10

When D.H.W. sensor (SS) is open or

short circuited, the boiler function

in C.H. and DHW and the display will

show alarm “AL 10”. Replace the sensor

because the message disappears.

–

ACTIVATION OF THE EXHAUST

TEMPERATURE SENSOR ERROR “AL

13” (fig. 22/d)

The activation of the exhaust fumes

sensor causes the boiler to stop and

the display will show AL 13.

Press the key

of the controls to

start up the boiler again.

–

EXHAUST TEMPERATURE SENSOR

ERROR “AL 14”

When the exhaust fumes sensor is

opened or short-circuited, the boiler

stops and the displays shows anomaly

AL 14.

–

FAN ERROR “AL 15”

If the fan speed is not within the rated

speed range , the display will show

“AL 15. If the problem persists for more

than two minutes the boiler will stop

for thirty minutes and then attempt to

resume working.

4.7

COMMISSIONING AND

ROUTINE

SERVICE

Commissioning and servicing can only

be done by a qualified engineer.

4.7.1 Commissioning

PLEASE NOTE: The combustion for this

appliance has been checked, adjusted

and preset at the factory for operation

on the gas type defined on the appliance

data plate.

However it is advisable to check

for correct combustion having first

checked:

- That the boiler has been installed in

accordance with these instructions.

- The integrity of the flue system and

the flue seals.

- The integrity of the boiler combustion

circuit and all the relevant seals.

The following procedure should be

done after installation a gas purge and

tightness/drop test have been made.

Ensure that the auto air vent (12 fig. 3) is

opened, turn the electrical supply on.

With the boiler on standby fill the system

and pressurise to 1.5 bar.

Ensure that the pump has been manually

rotated.

Open the gas cock, press the “ mode

key” (fig. 12).

Check the operational (working) gas

inlet pressure.

Set up the boiler to operate at maximum

rate as described in 4.5.1 (Chimney

sweep]).

With the boiler operating in the maximum

rate condition check that the operational

(working) gas pressure at the inlet test

point (see fig 16 item 1) is 21 mb +/- 2

mb.

Ensure that this inlet pressure can be

obtained with all other gas appliances in

the property working.

The boiler will attempt to light.

Press “ mode key” (fig. 12).

The burner will extinguish.

Turn on a DHW tap fully (preferably the

bath tap).

Set the controls to the required values as

shown in the user guide.

Complete the Benchmark sheet enclosed

in this manual.

Explain controls and operation to the

user.

Leave all documentation with the user.

4.7.2 PAR 15 maximum Heating Power

PAR 15 (parameter 15) is set as default

at 81% of the maximum boiler heating

output. This value should be adjusted to

correctly represent the actual heating

requirement for the installation.

4.8

ROUTINE SERVICE

To comply with the conditions of any

extended warranty offered and to

ensure continued safe and efficient

operation, the boiler must be serviced

at regular intervals, at least once a year.

This service must be recorded in the

Benchmark section of this manual.

It is the law that a competent person

such as a Gas Safe Register registered

engineer, must carry out any service

work.

4.8.1 Combustion Check (fig. 23)

Competence to carry out the check of

combustion performance.

PLEASE NOTE: BS 6798: 2009

Specification fro installation and

maintenance of gas-fired boilers of

rated input not exceeding 70 kw net

advises that:

* The person carrying out a combustion

measurement should have been

assessed as competent in the use of a

flue gas analyser and the interpretation

of the results;

* The flue gas analyser should be one

Fig. 22/b

Fig. 22/c

Fig. 22/d

Summary of Contents for COMFORT 30

Page 3: ......

Page 28: ...28 7 EXPLODED VIEWS...

Page 29: ...29...

Page 45: ...NOTES...

Page 46: ...NOTES...

Page 47: ......

Page 48: ...iqe co uk Trade House BA22 8RT Phone 0800 0152252...