SECTION 11—BATTERIES

Part No. 1125075

109

Pronto® Series

3. Remove the fuse holder from left side of charger next to battery charger cable and

perform one of the following:

• If fuse is bad, replace with new 250V, 4 amp fuse.

• If fuse is good, replace charger. Refer to Replacing the On-Board Battery Charger

on page 109.

4. Connect joystick and turn power On. Refer to Disconnecting/Connecting the Joystick

on page 123.

5. Perform one of the following:

• If wheelchair functions, install top shroud. Refer to Removing/Installing the Top

Shroud on page 87.

• If wheelchair does not function, replace charger. Refer to Replacing the On-Board

Battery Charger on page 109.

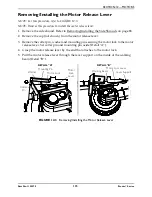

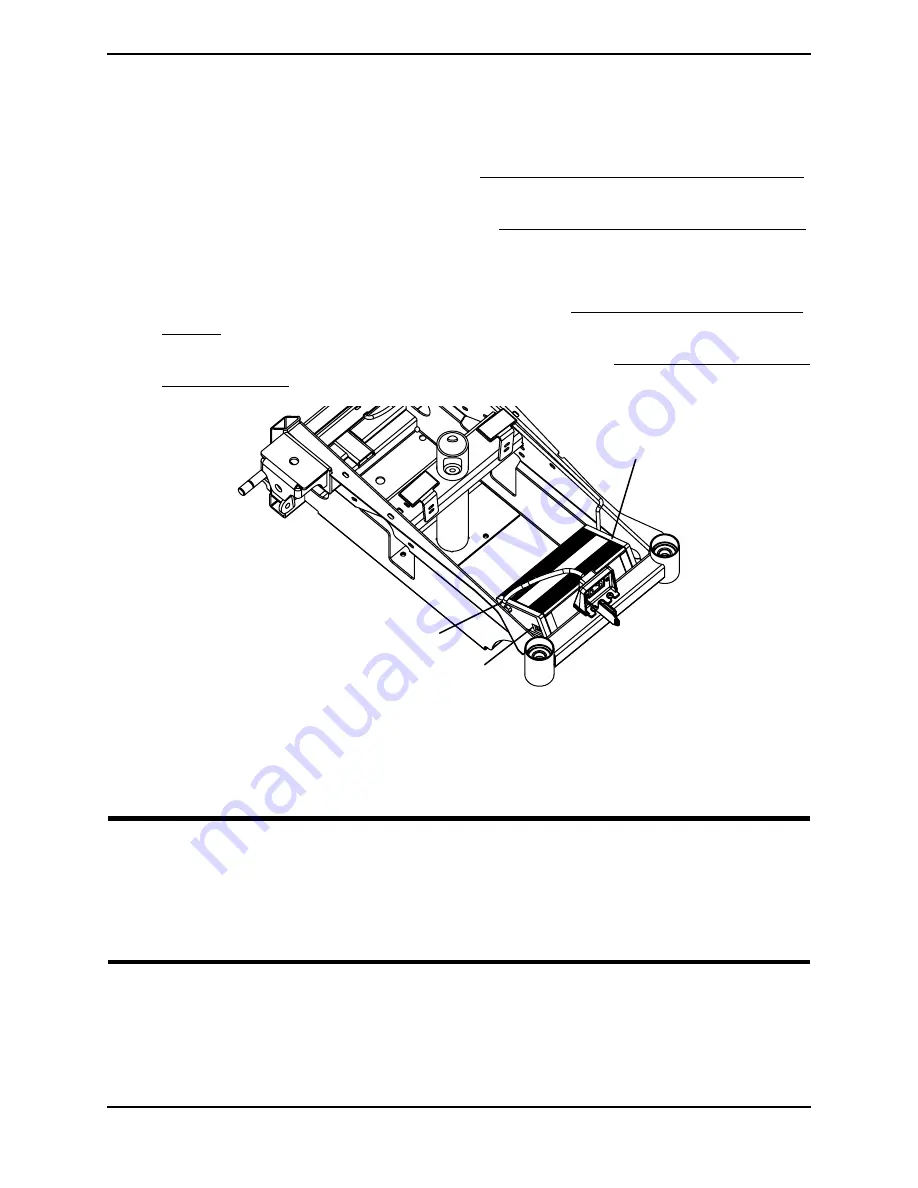

FIGURE 11.6

Replacing the On-Board Battery Charger Fuse

Replacing the On-Board Battery Charger

WARNING

DO NOT replace the battery charger fuse with anything other than a 250V 4 Amp

fuse. Otherwise, equipment damage and/or personnel injury may occur.

DO NOT attempt to remove the battery charger with power applied to the

wheelchair. Otherwise, equipment damage and/or personnel injury may occur.

NOTE: For this procedure, refer to FIGURE 11.7 on page 111.

NOTE: Take note of position and orientation of battery charger cables and tie-wraps for

reinstallation.

NOTE: The output of the battery charger is fused with a 250V, 4 amp fuse. The fuse holder is

located at the left side of the charger as it is mounted to the wheelchair. This fuse should be checked

Fuse Holder with 250V,

4 amp Fuse

Charger

Battery Charger Cable