Technical specifications

INTORQ | BA 14.0217 | 09/2019

23

5.3

Brake torques

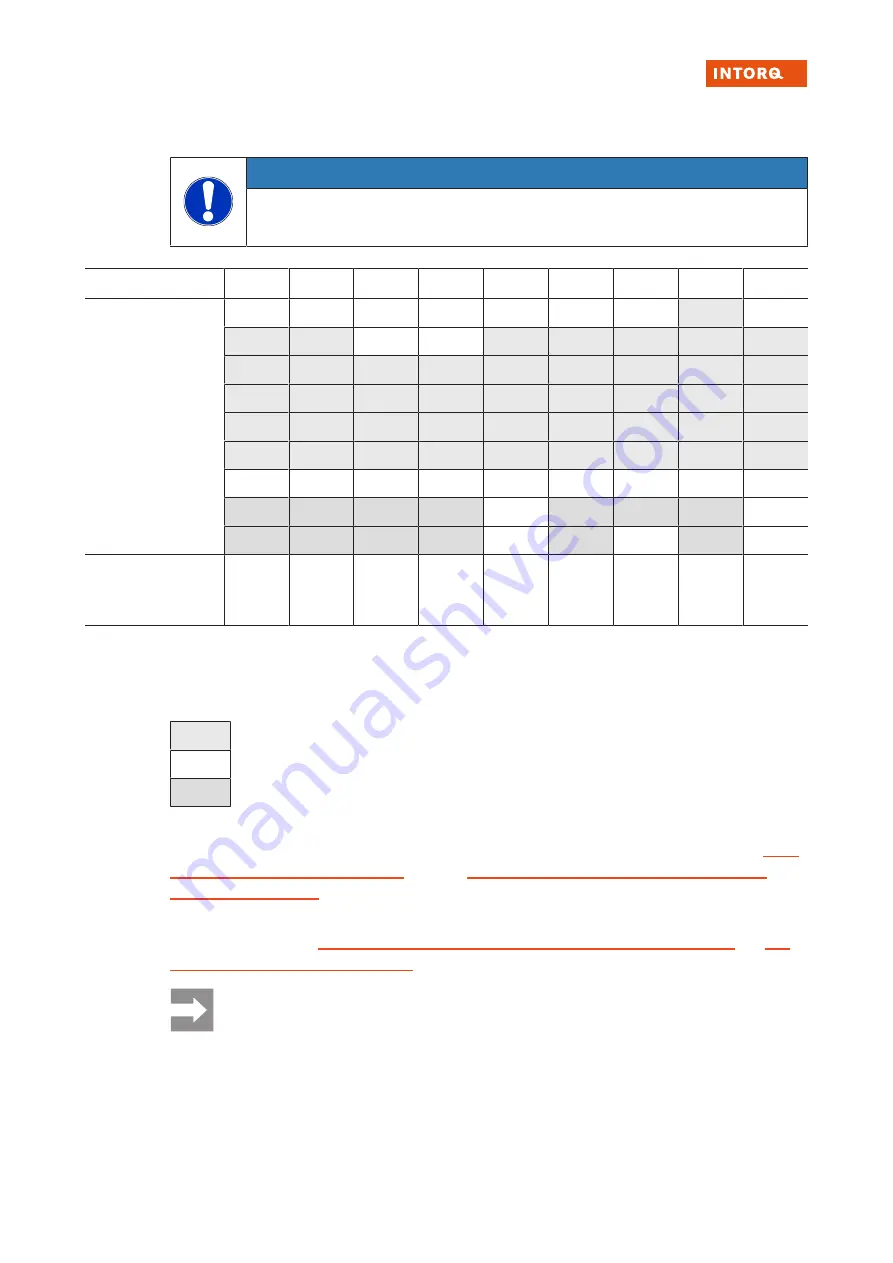

NOTICE

Please observe that engagement times and disengagement times change depending on

the brake torque.

Size

06

08

10

12

14

16

18

20

25

Rated torque M

K

[Nm]

of the brake, rated

value at a relative

speed of rotation of

100 rpm

Standard lining (ST)

and wear-resistant lin-

ing (WR)

80 E

1.5 E

3.5 N/E/L

25 N/E

35 N/E

65 N/E

115 N/E

175 N/E

2 N/E/L

4 E

7 N/E/L

14 N/E/L

35 N

45 N/E

80 N/E

145 N/E

220 N

2.5 N/E

5 N/E

9 N/E

18 N/E

40 N/E

55 N/E

100 N/E

170 N/E

265 N/E

3 N/E/L

6 N/E/L

11 N/E/L

23 N/E/L

45 N/E

60 N/E

115 N/E

200 N/E

300 N/E

3.5 N/E/L

7 N/E/L

14 N/E/L

27 N/E/L

55 N/E

70 N/E

130 N/E

230 N/E

350 N/E

4 N/E/L

8 N/E/L

16 N/E/L

32 N/E/L

60 N/E

80 N/E

150 N/E

260 N/E

400 N/E

4.5 N/E

9 N/E

18 N/E

36 N/E

90 N/E

165 N/E

290 N/E

5 E

10 E

20 E

40 E

100 N/E

315 N/E

Torque reduction per

detent [Nm], for design

type E

0.2

0.35

0.8

1.3

1.7

1.6

3.6

5.6

6.2

Tab. 2:

Braking torques and possible brake torque reduction: Adjustable for the design types

N Type without brake torque adjustment

E Type with brake torque adjustment

L Type in the long-life version

Operating brake (s

Lmax

approx. 2.5 x s

LN

)

Standard braking torque

Holding brake with emergency stop (s

Lmax.

approx. 1.5 x s

LN

)

For basic module E, the brake torque can be reduced using the torque adjustment ring in the stator. The

adjustment ring may only be unscrewed until the maximum protrusion (overhang) h

Emax

data for air gap specifications, Page 24

table and Brake torque reduction (for the optional adjustable

When using a standard friction lining, the maximum speeds and friction work Q

R

per brake frame size, as

specified in the sections Dust explosive atmosphere (zone 22: non-conductive dusts), Page 31 and Gas

explosive atmosphere (zone 2), Page 33, shall be applicable.

Notice

A version of the double spring-applied brake using HFC (high-friction coefficient) linings is not

permitted.