14

513 01 3402 02

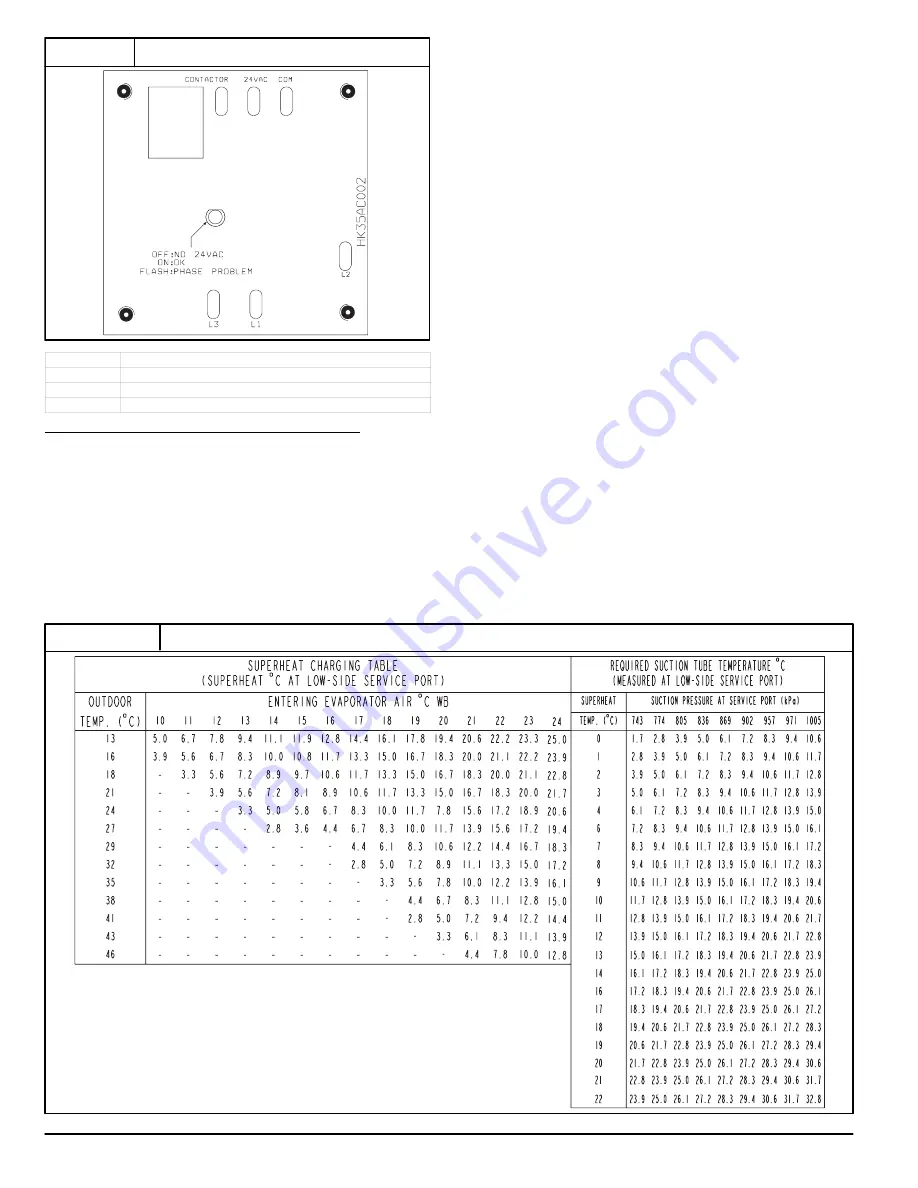

FIGURE 13

Phase Monitor Control and LED Indicators

LED

STATUS

OFF

No Call for compressor operation

FLASHING

Reversed phase

ON

Normal

Checking and Adjusting Refrigerant Charge

The refrigerant system is fully charged with R

−

410A refrigerant

and is tested and factory sealed.

NOTE

: Adjustment of the refrigerant charge is not required

unless the unit is suspected of not having the proper R

−

410A

charge.

A superheat charging chart is attached to the inside of the

compressor access panel (see FIGURE 16). The chart includes

the required suction line temperature at given suction line

pressures and outdoor ambient temperatures.

An accurate thermocouple

−

or thermistor

−

type thermometer,

and a gauge manifold are required when using the superheat

charging method for evaluating the unit charge. Do not use

mercury or small dial

−

type thermometers because they are not

adequate for this type of measurement.

NOTE

: Allow system to operate for a minimum of 15 minutes

before checking or adjusting refrigerant charge.

IMPORTANT

: When evaluating the refrigerant charge, an

indicated adjustment to the specified factory charge must always

be very minimal. If a substantial adjustment is indicated, an

abnormal condition exists somewhere in the cooling system,

such as insufficient airflow across either coil or both coils.

Proceed as follows:

1. Remove cap from low pressure service fitting.

2. Using hoses with valve core depressors, attach low pres-

sure gauge hose to low pressure service fitting.

3. Start the unit in cooling mode and let run until system

pressures stabilize.

4. Measure and record the following:

a. Outdoor ambient

−

air temperature (

°

C) db.

b. Evaporator inlet

−

air temperature (

°

C) wb.

c. Suction

−

tube temperature (

°

C) at low

−

side service

fitting.

d. Suction (low

−

side) pressure (kPA).

5. Using “Cooling Charging Tables” compare outdoor

−

air

temperature (

°

C) db with the entering evaporator air

temperature (

°

C) wb to determine desired superheat

temperature. (See FIGURE 14).

6. Using the superheat value in step 5, locate the intersec-

tion of the required superheat with the suction pressure

previously measured. Note the required suction tube

temperature. Using a tolerance of +/

−

(1.7

°

C), add refri-

gerant if actual temperature is higher than charted suction

tube temperature, or remove refrigerant if actual temper-

ature is lower than charted suction tube temperature.

NOTE

: If the problem causing the inaccurate readings is a

refrigerant leak, refer to Check for Refrigerant Leaks section.

FIGURE 14

Cooling Charging Table

−

Superheat

50ES500443 - 2.0