User’s Information Manual

10

441 02 2011 00

1. Turn

OFF

power to furnace.

2. Remove compartment door.

3. Reach up above right side of blower, and lift dirty filters out of

rack at top of furnace.

4. Straighten up filters and pull straight down at side of blower.

Pull out through right side of door opening.

5. Inspect the filter(s) and replace or clean washable types. If

filter is aluminum mesh, it should be recoated with filter coat-

ing spray.

6. Reinstall the filters in the filter rack.

7. Reinstall blower compartment door.

8. Turn

ON

electric power to the furnace.

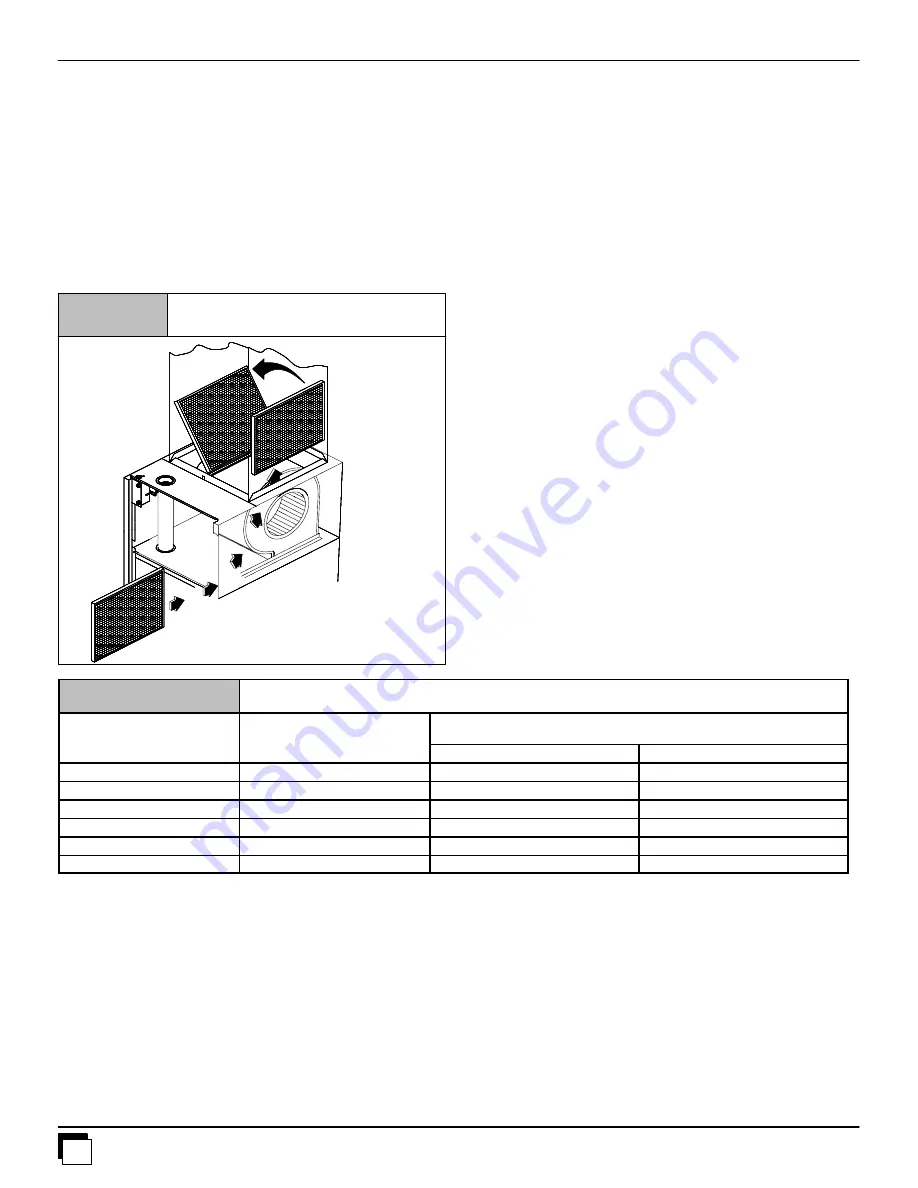

Downflow Filter Replacement

*8DNL

Right Side

Left Side

Figure 9

25--21--16a

External Filter Rack

A plastic end cap is inserted in the filter rack after the filter is

installed. The end cap keeps air from escaping around the open

end of the filter rack. See

Figure 7

for removal of filter.

Filter racks attached to the furnace are made so the filter simply

slides out one end for removal.

1. Turn

OFF

electric power to furnace.

2. Remove the end cap from the filter rack.

3. Slide the filter out of the filter rack.

4. Inspect the filter(s) and replace or clean washable types. If

filter is aluminum mesh it should be recoated with filter coating

spray.

5. Reinstall the end cap in the filter rack.

6. Turn furnace on.

Internally Mounted Filter

1. Turn

OFF

power to furnace.

2. Remove blower door.

3. Slide filter straight out toward you. (See

Figure 8

.)

4. Inspect the filter(s) and replace or clean washable types. If

filter is aluminum mesh it should be recoated with filter coating

spray.

5. Replace blower door

6. Turn on electric power to furnace.

Lubrication

The blower motor and the combustion air blower are prelubricated

by the manufacturer and

DO NOT

require oiling.

Table 1

Recommended Filter Sizes

furnace Size

Heating Input

Nominal Air Flow

Cubic Feet

Recommended Filter Sizes

Sq. In. Surface Area/Nominal Size (inches)

Heating Input

1000 x Btuh

Cubic Feet

per Minute (CFM)

Disposable Filters

Cleanable Filters

50

800--900

500 or 20 x 25

350 or 14 x 25

50, 75, and 100

1100--1300

350 or 14 x 25 (2Req.)

350 or 14 x 25

50, 75, 100, and 125

1300--1500

400 or 16 x 18 (2Req.)

400 or 16 x 18

80, 100, and 125

1500--1700

500 or 20 x 25 (2 Req.)

500 or 20 x 25

125

1900--2100

600 or 20 x 30 (2 Req.)

500 or 20 x 25

150

2300--2500

600 or 20 x 30 (2 Req.)

720 or 24 x 30

Qualified Service Agency Checks

When the furnace is being inspected for condition and operation

have the Qualified Service Agency check the following items.

1. Check all flue gas passages including main and pilot burners,

heat exchanger, and vent.

2. Check electrical wiring and connections.

3.

Check supply and return air ducts for leakage, blockage and

connections to furnace.

4.

Check circulating air blower wheel and motor. Clean them if

required.

5.

Perform an operational checkout on the furnace to be sure

safety controls function and that furnace operates properly.

For additional information, the Qualified Service Agency can

consult the installation instructions for the furnace.