Installation Guide

51

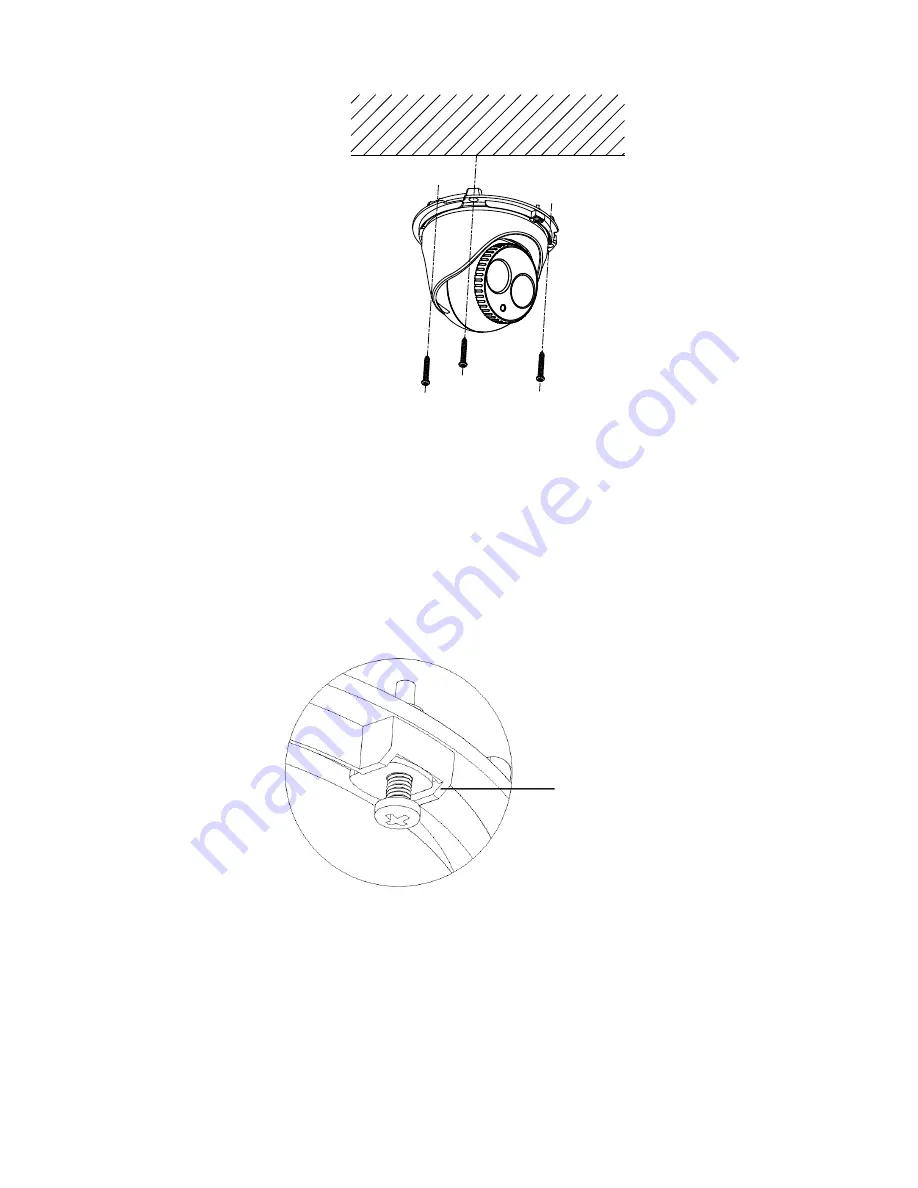

6. Adjust the lens.

a) Loosen the locking screw using a Philips screw

driver.

b) Rotate the lens assembly to adjust the pan angle.

Rotate the lens assembly to adjust the tilt angle.

c) Tighten the locking screw to secure the lens at the

desired surveillance angle.

Locking screw

Summary of Contents for TVB-5301

Page 1: ...TruVision Series 3 IP Camera Installation Guide P N 1073188 EN REV E ISS 22SEP17 ...

Page 4: ......

Page 67: ......

Page 68: ......