03523479_ed16

3

EN

Placing Tool in Service

Lubrication

Ingersoll Rand No. 28 Ingersoll Rand No. 50

Always use an air line lubricator with this motor.

We recommend the following Filter-Lubricator-Regulator Unit:

No. C28241-800

Where the lubricator cannot be permanently mounted, use

Ingersoll Rand No. 3LUB8 Lubricator.

We recommend the use of an air line lubricator in the air supply

line. Attach the unit as close to the tool as practical. For permanent

installations, we recommend using an Ingersoll Rand

C28241-800 Filter-Lubricator-Regulator Unit. These units have 1/2”

pipe tap inlet and outlet. The 3LUB8 has 1/6 pt (79 ml) capacity; the

C28241-800 has 6 oz (177 ml) capacity. Larger capacity units may be

used, but do not use a unit having less than 1/2” pipe tap inlet and

outlet.

After each 40,000 cycles or one month, whichever occurs first,

inject 1.5 cc of Ingersoll Rand No. 28 Grease into the Grease

Fitting (30).

Direction of Spindle Rotation

Series 3800 Nonreversible Motors can be assembled so that the

Spindle rotates either clockwise or counter-clockwise. To reverse the

direction of the spindle rotation:

1. Remove the motor assembly from the Motor Housing (15).

2. Remove one End Plate and Bearing from the motor.

3. Lift the Cylinder (16) from the Rotor (13), turn it end for end, and

slide it back over the Rotor.

4. Install the End Plate and Bearing assembly on the Rotor Hub and

install the assembled motor in the Housing.

5. Remove the three Backhead Cap Screws (3) and rotate the

Backhead (2) and Backhead Gasket (6) 90° so that the cavity in

the face of the Backhead is in alignment with the alternate set of

holes in the back face of the Motor Housing. When the Backhead

is correctly applied, the cavity will be over the letter “F” for

counterclockwise spindle rotation (when facing the end of the

Spindle), and over the letter “R” for clockwise rotation.

The rotational direction of an assembled Nonreversible Series

3800 Motor can be determined by removing the Air Strainer (1)

and looking through the tapped opening to see whether the

letter “F” or letter “R” is visible. Apply the Backhead on Series

3840 Reversible Motors so that each inlet port aligns with a group

of three holes through the housing rear wall.

NOTICE

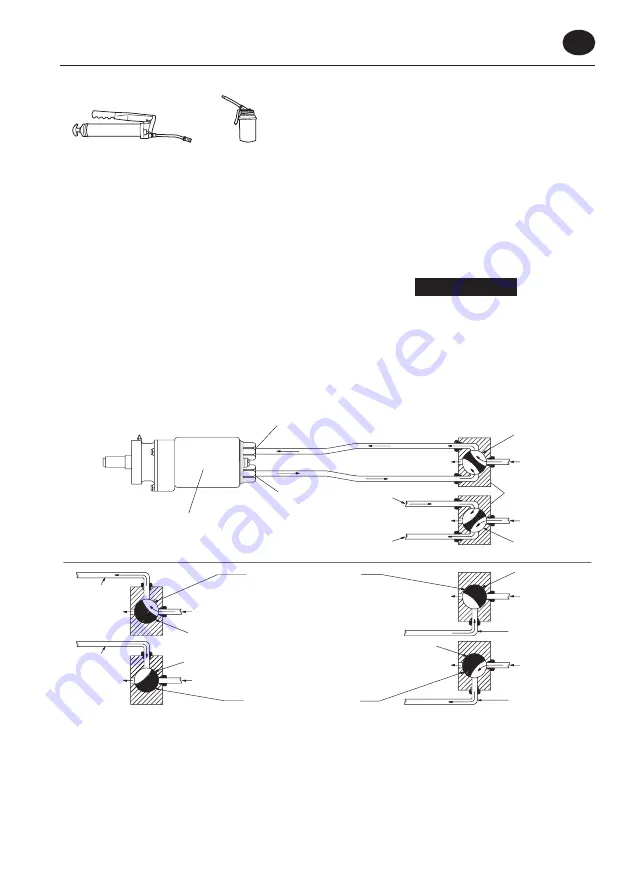

A four-way Throttle Valve (whether manually, remotely, or

automatically controlled) must be used in the air supply

line to Series 3840 reversible motors, as one motor inlet is

expelling secondary exhaust air, and therefore must be open to

atmosphere whenever the opposite inlet is admitting live air to

the motor. The use of any throttle valve that closes or restricts

the secondary exhaust line will result in sufficient back pressure

to drastically reduce the speed and power of the motor.

When the application requires a separate Throttle Valve in each

air line, the two three-way valves must be used.

Forward Inlet

Reverse Inlet

Reversible Motor

Exhaust

Exhaust

Air line to

forward inlet

Air line to

reverse inlet

Valve positioned for

forward operation

of Motor

Valve positioned for

reverse operation

of Motor

Valve positioned for

forward operation

of Motor

Valve positioned for reverse

operation of Motor

Valve positioned for

reverse operation

of Motor

Valve positioned for

forward operation

of Motor

Air line to

forward inlet

Air line to

forward inlet

Air line to

reverse inlet

Air line to

reverse inlet

Live Air

Live Air

Live Air

Live Air

Exhaust

Exhaust

Exhaust

Exhaust

Live Air

Live Air

Four-way

Throttle

Valve

Single four-way Valves for controlling forward and reverse operation of Motor

Two three-way Valves for controlling forward and reverse operation of Motor

Relative positions of Valves for

forward operation of Motor

Relative positions of Valves for

reverse operation of Motor

Three-way Throttle

Valve in air line to

reverse inlet

Three-way Throttle

Valve in air line to

forward inlet

(Dwg. TPB176)

Summary of Contents for MULTI-VANE 3800 Series

Page 11: ...Notes...