Only allow

Ingersoll Rand

trained technicians to perform maintenance on this product. For additional information contact

Ingersoll Rand

Factory or nearest

Distributor.

For additional supporting documentation refer to Table 1 ‘Product Information Manuals’ on page 2.

Manuals can be downloaded from www.irtools.com.

The use of other than genuine

Ingersoll Rand

replacement parts may result in safety hazards, decreased performance and increased maintenance and will invalidate all warranties.

The original language of this manual is English.

Refer all communications to the nearest

Ingersoll Rand

Office or Distributor.

Table 1: Product Information Manuals

Publication

Part/Document Number Publication

Part/Document Number

Product Safety Information Manual

MHD56295

Product Information Manual

MHD56414

Product Parts Information Manual

MHD56415

INSPECTION

Perform frequent inspections on equipment in regular service. Refer to Product

Information Manual.

n

Periodic Inspection

Refer to Table 2 ‘Inspection Classifications’ on page 2 for suggested inspection

classifications for Periodic Inspection Intervals. Select conditions most appropriate

to application.

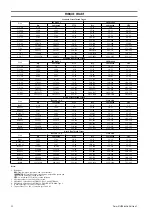

Table 2: Inspection Classifications

Conditions

Normal

Heavy

Severe

Typical Use (operating time)

Infrequent

Regular

Continual/Constant

Load Range

60% of Capacity 75% of Times Used

80% of Capacity 75% of Times Used

100% of Capacity 75% of Times Used

Installation

Protected/Enclosed/Dry

Not Sheltered/Exterior

Full Exposure

Atmosphere

Clean/Non-Corrosive

Dirty/Non-Corrosive/Freshwater Marine

Dirty/Corrosive/Saltwater Marine

Climate

Dry/Stable Temperature

Wet/Moderate Temperature Fluctuations

Wet/Severe Temperature Fluctuations

Maintain written records of periodic inspections to provide a basis for continuing

evaluation. Inspect all items listed in ”Frequent Inspection”. Refer to Product

Information Manual. Also inspect the following at the suggested intervals

recommended in Table 5, ‘Maintenance Interval Chart’ on page 3.

1.

Fasteners.

Check all rivets, split pins, capscrews and nuts. Replace if missing or

tighten if loose.

2.

All Components.

Inspect for wear, damage, distortion, deformations and

cleanliness. If external evidence indicates the need, disassemble. Check gears,

shafts, bearings, sheaves, chain guides, springs and covers. Replace worn or

damaged parts. Clean, lubricate and reassemble.

3.

Hooks.

Inspect hooks carefully for cracks using magnetic particle or other

suitable non-destructive method. Inspect hook retaining parts. Tighten or repair

if necessary.

Table 3: Hook Throat Normal and Discarded Width

Hoist Model

Capacity metric tons

Throat Width

Discard Width

in.

mm

in.

mm

LCA750T

7.5

5.98

152

6.85

174

4.

Load Chain Sprocket.

Check for damage or excessive wear. Replace if necessary.

Observe the action of load chain feeding through hoist. Do not operate a hoist

unless load chain feeds through hoist and hook block smoothly and without

audible clicking or other evidence of binding or malfunctioning.

5.

Motor.

If performance is poor, disassemble motor and check for wear or damage

to bearings and shafts. Parts should be cleaned, lubricated and reassembled.

Replace worn or damaged parts.

6.

Brake.

Raise a load equal to rated capacity of hoist a few inches (cms) off the

floor. Verify hoist holds the load without drift. If drift occurs, disassemble.

Remove brake discs as described in “MAINTENANCE” on page 5. Check and clean

brake parts each time hoist is disassembled. Replace brake discs if grooves are

no longer visible.

7.

Supporting Structure.

Check for distortion, wear and continued ability to support

a load.

8.

Trolley

. Check that the trolley wheels track beam properly and trolley is correctly

adjusted in accordance with manufacturer’s literature. Check that wheels and

beam are not excessively worn and inspect side plates for spreading due to

bending. Do not operate hoist until problem has been determined and corrected.

9.

Labels and Tags.

Check for presence and legibility. Replace if necessary.

10.

Load Chain End Anchors.

Ensure both ends of load chain are securely attached.

Secure if loose, repair if damaged, replace if missing. Check chain stoppers are

correctly installed and functional.

11.

Load Chain.

Check the chain for stretching. Measure the load chain over five link

sections all along chain, paying particular attention to the most frequently reeved

links. Refer to Dwg. MHP0041 on page 2,

A:

Gauge Length. When any five links

in the working length reach or exceed the discard length, replace entire chain.

Refer to Table 4 ‘Load Chain Normal and Discard Length’ on page 2. Always use

genuine

Ingersoll Rand

replacement chain. Zinc plated load chain is standard on

Liftchain hoists.

Table 4: Load Chain Normal and Discard Length

Hoist Model

Chain Size

Normal Length

Discard Length

mm

in.

mm

in.

mm

LCA750T

32 x 90

17.72

450

18.03

458

Gauge Length

A

(Dwg. MHP0041)

12.

Chain Container

(optional feature). Check for damage or excessive wear and that

chain container is securely attached to the hoist. Secure or replace if necessary.

13.

Limit Switch.

Check limit switches function correctly.

14.

Emergency Stop.

During hoist operation verify emergency shut-off by activating

button. All operation must stop quickly. Stop button must reset properly.

n

Records and Reports

Inspection records, listing all points requiring periodic inspection should be

maintained for all load bearing equipment. Written reports based on severity of

service, should be made of the condition of critical parts as a method of documenting

periodic inspection. These reports should be updated, signed by the person who

performed the inspection, and kept on file where they are readily available for review.

2

Form MHD56416 Edition 1