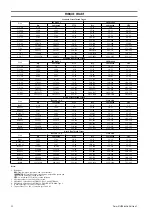

PERIODIC MAINTENANCE

Table 5: Maintenance Interval Chart

Normal Application

The following work can be completed by owner maintenance personnel

System Air Filter

Inspect system air filter every 45 days or 125 hours.

Grease Fittings

Lubricate grease fittings every 180 days or 500 hours.

Gearbox Oil Level

Check oil level in gearbox every 120 days or 340 hours. Replace oil yearly.

It is recommended that the following work be completed by an Ingersoll Rand trained service technician.

Standard Components

1 year or

1,000 hrs

2 years or

2,000 hrs

3 years or

3,000 hrs

4 years or

4,000 hrs

5 years or

5,000 hrs

6 years or

6,000 hrs

8 years or

8,000 hrs

Inspect Motor

X

X

X

X

Inspect Disc Brake

X

X

Inspect Gearbox

X

X

Inspect Controls

X

X

X

X

Inspect System, Housings and Main Frames

X

X

X

X

Inspect Trolley Motor

X

X

X

Inspect Trolley Wheel Assembly

X

X

X

Inspect Trolley Gearbox

X

X

X

Chain Container

X

X

X

Heavy Application

The following work can be completed by owner maintenance personnel

System Air Filter

Inspect system air filter every 30 days or 100 hours.

Grease Fittings

Lubricate grease fittings every 90 days or 250 hours.

Gearbox Oil Level

Check oil level in gearbox every 90 days or 250 hours. Replace oil yearly.

It is recommended that the following work be completed by an Ingersoll Rand trained service technician.

Standard Components

1 year or

1,000 hrs

2 years or

2,000 hrs

3 years or

3,000 hrs

4 years or

4,000 hrs

5 years or

5,000 hrs

6 years or

6,000 hrs

8 years or

8,000 hrs

Inspect Motor

X

X

X

X

Inspect Disc Brake

X

X

X

Inspect Gearbox

X

X

X

Inspect Controls

X

X

X

X

Inspect System, Housings and Main Frames

X

X

X

X

Inspect Trolley Motor

X

X

X

Inspect Trolley Wheel Assembly

X

X

X

Inspect Trolley Gearbox

X

X

X

Chain Container

X

X

X

Severe Application

The following work can be completed by owner maintenance personnel

System Air Filter

Inspect system air filter every 30 days or 100 hours.

Grease Fittings

Lubricate grease fittings every 90 days or 250 hours.

Gearbox Oil Level

Check oil level in gearbox every 90 days or 250 hours. Replace oil yearly.

It is recommended that the following work be completed by an Ingersoll Rand trained service technician.

Standard Components

1 year or

1,000 hrs

2 years or

2,000 hrs

3 years or

3,000 hrs

4 years or

4,000 hrs

5 years or

5,000 hrs

6 years or

6,000 hrs

7 years or

7,000 hrs

Inspect Motor

X

X

X

X

X

X

Inspect Disc Brake

X

X

X

X

X

Inspect Gearbox

X

X

X

Inspect Controls

X

X

X

X

X

X

Inspect System, Housings and Main Frames

X

X

X

X

X

X

Inspect Trolley Motor

X

X

X

X

X

X

Inspect Trolley Wheel Assembly

X

X

X

Inspect Trolley Gearbox

X

X

X

Chain Container

X

X

X

Note:

Hours are for actual system operation. Perform an annual hoist load test for all applications.

Recommend complete general overhaul.

Form MHD56416 Edition 1

3