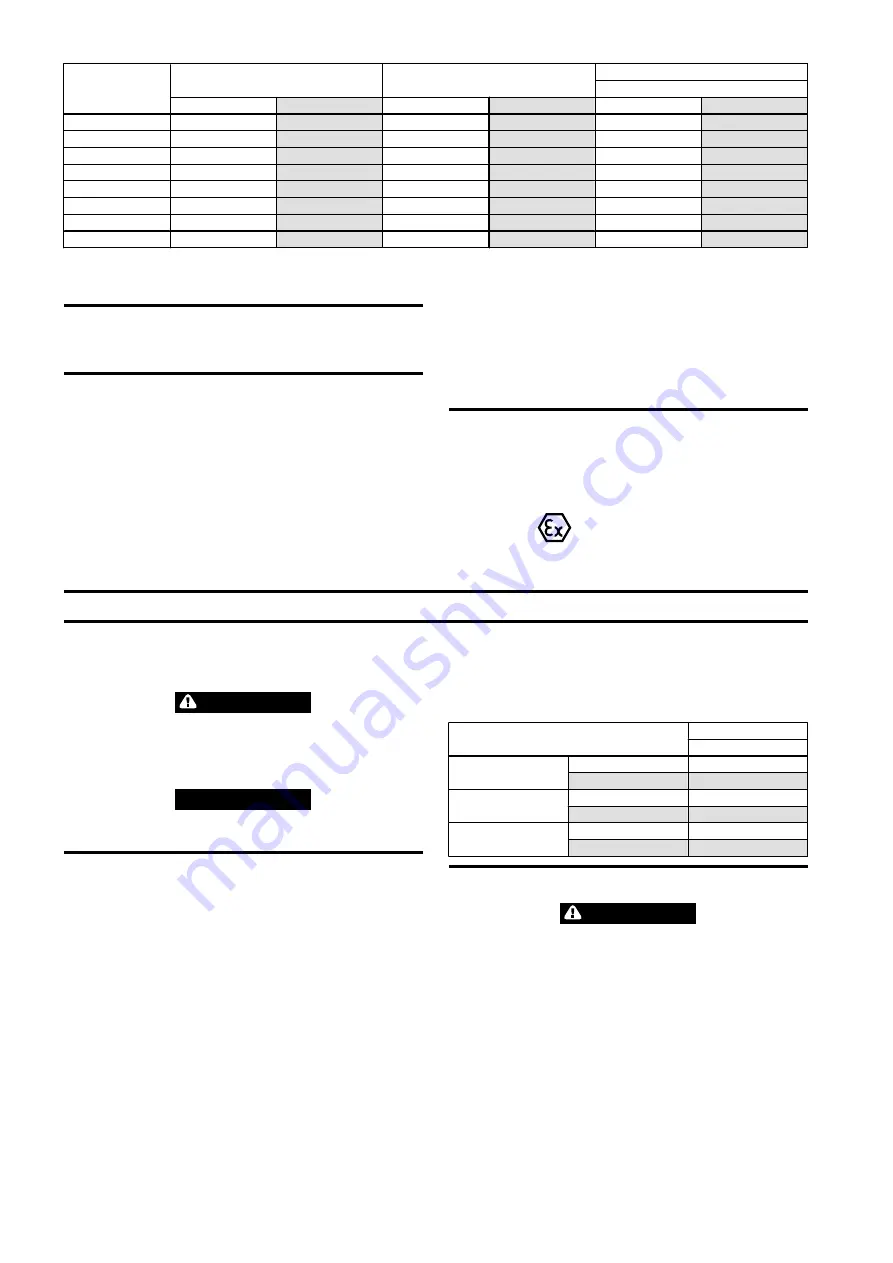

Layer

Line Speed @ 150 kg (330 lb) Load

Minimum Load for Emergency Lowering

Wire Rope Storage Capacity **

12 inch (305 mm) Drum

fpm

mpm

lb

kg

ft

m

1

82

25

200

91

86

26

2

85

26

187

85

178

54

3

87

26.5

176

80

275

84

4

89

27

166

75

378

115

5

91

27.7

158

72

487

148

6

93

28.3

150

68

602

183

7

94

28.6

140

64

723

220

8 (1)

95

29

136

62

849

259

** Wire rope storage capacity based on DNV and NMD standards of 2.5 times wire rope diameter below drum flange. Wire rope storage capacities listed may vary from figures

stated elsewhere.

1. Full drum at rated operating pressure and line speed.

n

Capacity Information

FA150KGi Man Rider

™ winches are designed for lifting with a 5:1 minimum safety

factor at rated load.

n

Traceability

Load bearing parts are documented to provide traceability. Documentation includes

chemical and physical properties of raw material, heat treating, hardening, tensile

and charpy tests as required for the part.

Units with

M1

,

M2

or

M3

in the model code have traceable load bearing components.

M1

– Material Traceability certificates according to EN 10204 (Ex DIN 50049) 2.2 on

load bearing parts. Conformity documents affirm (by the manufacturer) that parts are

in compliance with requirements of the order, based on non-specific inspection and

testing (i.e. results are typical material properties for these parts).

M2

– Material Traceability certificates according to EN 10204 (Ex DIN 50049) 3.1b on

load bearing parts. Conformity documents affirm (by a department independent of

the manufacturing department) that actual parts are in compliance with requirements

of the order, based on specific inspection and testing (i.e. results are actual material

properties for these parts).

M3

– Material Traceability certificates according to EN 10204 (Ex DIN 50049) 3.1b on

load bearing parts. Conformity documents affirm (by a department independent of

the manufacturing department) that the actual parts used in the product are in

compliance with the order, based on specific inspection and testing (i.e. results are

actual material properties for these parts in a finished, as delivered condition).

Components with part numbers ending in CH are charpy parts for use under extreme

cold conditions. Traceability requirements must be stated when reordering these parts

for continued certification.

n

ATEX

Refer to labeling on product, located near or on data (name) plate, for specific ATEX

designation. Product not marked as such, are not suitable for use in any potentially

explosive atmosphere (ATEX). Refer to Product Safety and Maintenance Information

Manuals for further explanation.

II 2 GD c IIB 200°C X

(Dwg. MHP2584)

INSTALLATION

Winch gearbox and disc brake are supplied fully lubricated from factory. Check oil

levels and adjust as necessary before operating winch.

Refer to “LUBRICATION” section on page 9 for recommended oils. Prior to

installing winch, carefully inspect it for possible shipping damage.

CAUTION

• Owners and users are advised to examine specific, local or other regulations,

including American Society of Mechanical Engineers (ASME) and/or OSHA

Regulations which may apply to a particular type of use of this product before

installing or putting product to use.

NOTICE

• Prior to installation refer to Product Safety Information Manual.

n

Mounting

Care must be taken when moving, positioning or mounting winch. Winch has lifting

lugs bolted to both uprights to assist in moving the unit. Attach hooks or a suitable

sling to these lugs when moving winch. Refer to “SPECIFICATIONS” section

on page 3 to determine winch weight.

Mount winch so drum axis is horizontal and motor control valve pad is not more than

15 degrees off top vertical center. If winch is to be mounted in an inverted position,

the motor case must be rotated to position control valve pad at the top and adequate

clearance must be provided for control valve operation. Position winch to provide

unrestricted access to winch control valve. Do not mount winch in a vertical position,

with motor up or down. Reduction gear box lubrication is not designed for this type

of installation.

1. Winch mounting surface must be flat and of sufficient strength to handle rated

load plus the weight of the winch and attached equipment. An inadequate

foundation may cause distortion or twisting of the winch uprights and side rails

resulting in winch damage.

2. Make sure mounting surface is flat to within 1/16 inch (1.6 mm). Shim if

necessary.

3. Mounting bolts must be 5/8 inch NC (16 mm) Grade 8 or better. Use self-locking

nuts or nuts with lockwashers. Refer to Table 3 ‘Mounting Bolt Hole

4. Tighten mounting bolts evenly. Refer to “Torque Chart” in Product Maintenance

Information Manual for proper tightening values.

5. Maintain a fleet angle between lead sheave and winch of no more than 1-1/2

degrees. The lead sheave must be on a center line with the drum and, for every

inch (25 mm) of drum length, be at least 1.6 ft (0.5 m) from the drum. Refer to

Product Safety Information Manual.

Refer to Dwg. MHP2288 on page 11,

A.

Drum.

Table 3: Mounting Bolt Hole Dimensions

Dimension

Drum Length (inches)

12

“A”

inch

20

mm

508

“B”

inch

9

mm

229

“C”

inch

0.69

mm

18

n

Wire Rope

CAUTION

• Maintain at least 3 tight wraps of wire rope on the drum at all times.

• Do not use wire rope as a ground (earth) for welding.

• Do not attach a welding electrode to winch or wire rope.

• Install wire rope to come off drum for underwound operation (normal

application). Refer to Product Safety Information Manual.

Install winch so wire rope, when at take-off angle limits, does not contact mounting

surface or drum guard panels. Install winch with single part wire rope reeving only.

Refer to Dwg. MHP3149 on page 11.

A.

Adjust slack arm prior to use, for wire rope

take-off angle.

n

Wire Rope Selection

Consult a reputable wire rope manufacturer or distributor for assistance in selecting

the appropriate type and size of wire rope and, where necessary, a protective coating.

Use a wire rope which provides an adequate safety factor to handle the actual working

load and meets all applicable industry, trade association, federal, state and local

regulations.

4

Form MHD56470 Edition 4