Page 2 of 8

651785 (en)

Y

Read and heed all Warnings and Safety Precautions

before operation of this unit.

Y

Use only genuine ARO replacement parts to assure

compatible pressure rating and longest service life.

Y

Be certain anyone operating this equipment or fluid

system has been trained to use it safely.

WARNING

HIGH PRESSURE DEVICE. IMPROPER

USAGE OF THIS EQUIPMENT COULD RESULT IN

SERIOUS INJURY. The possibility of injection into

the flesh is a potential hazard. Wear approved

safety glasses or face shield and other equipment as

needed to prevent injury. Never allow any part of the

human body to come in front of or in contact with

the material outlet, the tip, or the material outlet

of the dispensing device. An injection injury can be

serious. If an injection accident should occur, it is very

important that you contact a qualified physician for

immediate treatment.

WARNING

MISAPPLICATION HAZARD. DO NOT USE

THE REGULATOR WHEN THE FLUID INLET PRESSURE

IS TOO HIGH FOR THEDESIGNED OPERATING RANGE.

Excessive inlet pressure can cause a Lock-Out

situation. Lock-Out occurs whenthe inlet pressure

isbeyondthe regulator’s springcapacity. THE

VALVE WILL NOT OPEN. Attempts to disassemble

componentswhile in a Lock-Out condition mayresult

in injury.

WARNING

COMPONENT RUPTURE. DO NOT OPERATE

REGULATOR AT AN INLET PRESSURE GREATER THAN

SPECIFIED. To avoid possible damage or personal

injury, DO NOT operate this unit at pressure higher

than the stated operating range as it appears on the

model plate.

WARNING

D I S A S S E M B LY H A Z A R D. D O N OT

DISASSEMBLE THIS REGULATOR WHEN IT IS UNDER

PRESSURE. RELIEVE PRESSURE IN THE PUMPING SYSTEM

BEFORE ATTEMPTING SERVICE OR DISASSEMBLY

PROCEDURES. Disconnect air lines and carefully bleed

pressure off the system. Be certain the system is not

maintaining pressure due to amaterial restriction in the

hose, line, dispensing device, or the spray or extrusion

tip. Failure to relieve pressure both up stream and

downstream may result in an injury upon disassembly.

WARNING

BONNET REMOVAL HAZARD. DO NOT

ATTEMPT TO REMOVE THE FOUR BONNET RETAINING

BOLTS WITHOUT FIRST RELIEVING THE TENSION ON THE

MAIN SPRING. Failure to relieve tension could result in an

accident upon disassembly.

WARNING

PREVENT FIRES. KEEP SOLVENTS AWAY

FROM HEAT, SPARKS OR OPEN FLAME. Keep containers

closed when not in use.Whenpumping, flushing or

recirculating volatile solvents, be certain the area is

adequately ventilated.

CAUTION

FLUSH SUPPLY LINE. Before installing

fluid regulator, blow the supply lines clear and flush

to remove contaminates.

OPERATING AND SAFETY PRECAUTIONS

INSTALLATION

y

Refer to the typical installation view which best applies.

y

Locate the regulator as close as possible to the spray gun

or dispensing device for best pressure control.

y

Identify the regulator INLET / OUTLET (flow direction).

The regulator is marked with an arrow on the body base

(see figure 8).

y

When flexible fluid lines are used, mount the regulator

securely using the (2) 1/4” - 20 threaded holes in the base

(see figure 8).

y

Flush supply line before installing regulator.

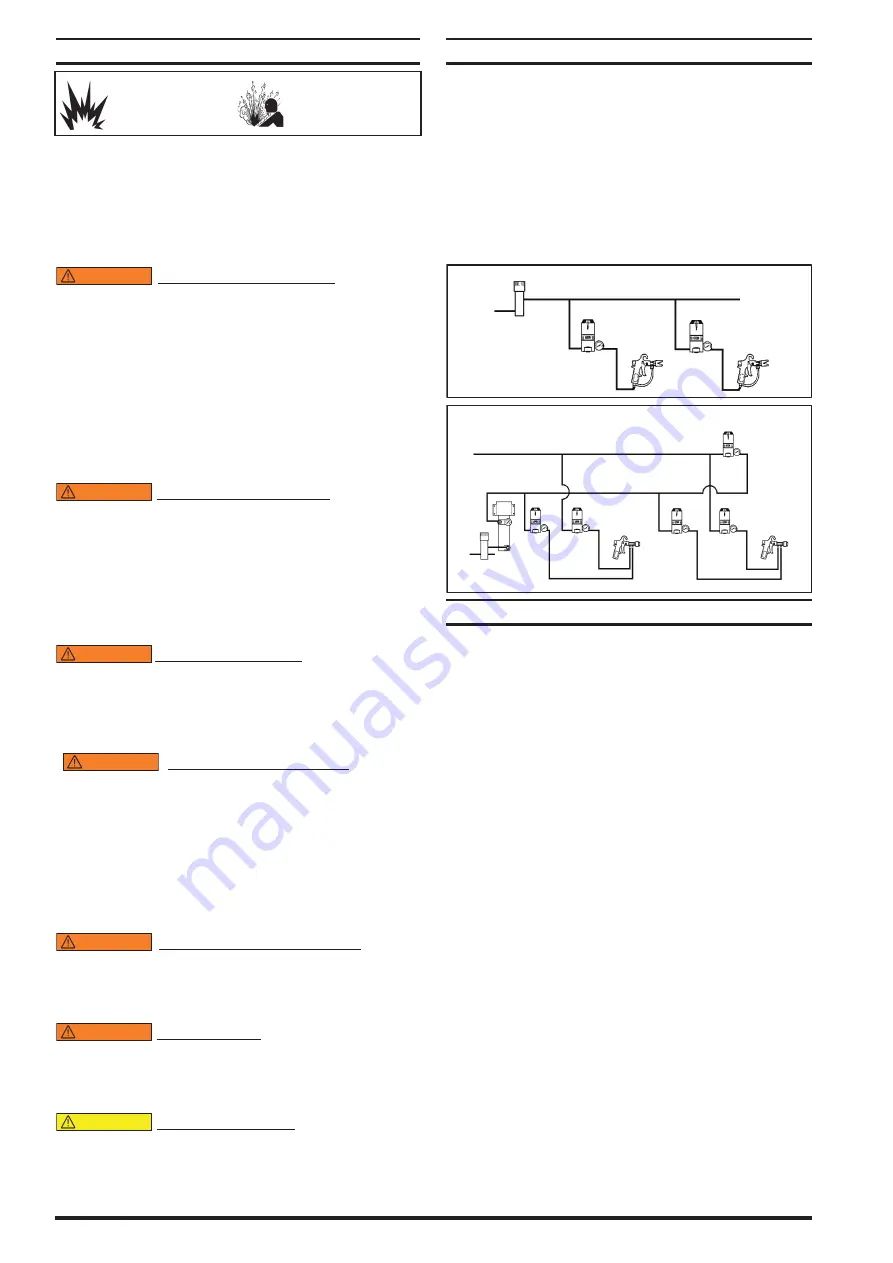

TYPICAL DEAD END SYSTEM

Filter

Down Stream

Regulator

Down Stream

Regulator

Figure 2

Figure 3

TYPICAL RECIRCULATING SYSTEM

Back Pressure

Regulator

Back Pressure

Regulator

Filter

Heater

Back Pressure

Regulator

Down

Stream

Regulator

Down

Stream

Regulator

OPERATING INSTRUCTIONS

Refer to page 4 and 5 for parts reference.

y

To INCREASE outlet pressure, turn the (6) adjusting screw

CLOCKWISE (see figure 4).

y

To DECREASE outlet pressure, turn the (6) adjusting

screw COUNTERCLOCKWISE (see figure 4).

NOTE: ARO Part Y106-109 Allen wrench is included to make

necessary pressure adjustments.

FLUSH-OUT FEATURE (see figure 5).

y

Flush the regulator periodically. The interval may vary de-

pending on the amount and type of material used.

y

By using a wrench and “flush-out” plug (provided), the

operator is able to move the entire spindle downward

and force the ball off the seat which should purge the

regulator of particle build-up.

NOTE: The flush-out procedure temporarily overrides the

adjusted pressure. It will not, however, affect the regulator

setting when flushing operation is completed.

FLUSH-OUT PROCEDURE

1. Remove spray gun or dispensing device, this will allow

any particles to clear from the system.

2. Insert (30) flush-out plug and turn clockwise until it

touches the (4) washer (see view on page 5).

3. Turn up to two turns maximum. This will allow the ball

to unseat and pass material at free flow (unregulated).

DO NOT attempt to turn further to avoid damage.

4. Turn the plug back to its original position.

SEAT PLUG FEATURE

The (29) plug located at the base of the regulator can be

removed for access to the ball and seat assembly for clean-

ing and inspection for wear. With this feature, the regulator

EXCESSIVE AIR PRESSURE

STATIC SPARK

HAZARDOUS MATERIALS

HAZARDOUS PRESSURE