20

Chapter 4 - Connections

XtrapulsEasy

™-DB - Installation Guide

4.3 - ACCESSORIES AND CONNECTIONS

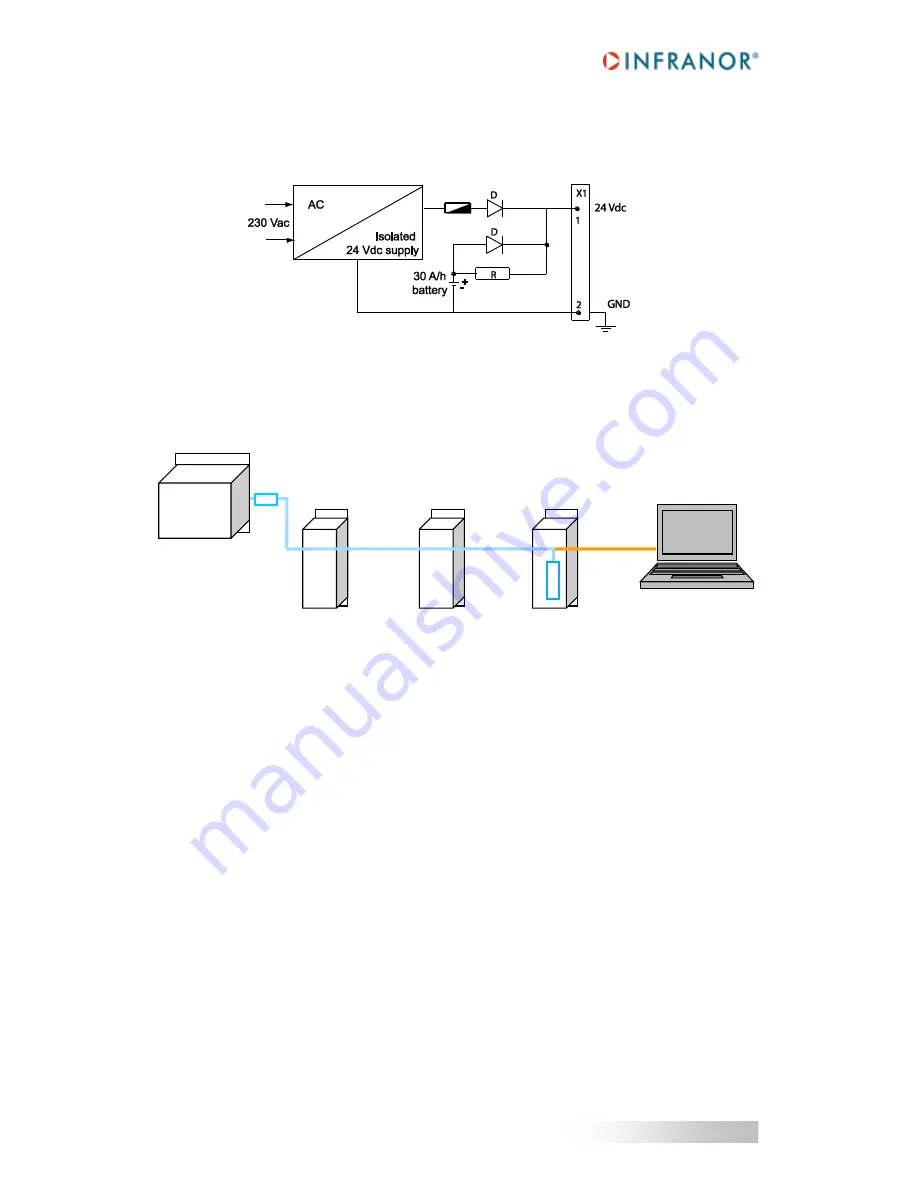

4.3.1 - Connection of a backup battery

The Xtrapuls

Easy™ drive consumption is less than 100mA with 24V

DC

. So, a 24V / 30A/h battery can keep the

drive powered during approx. 10 days. This backup method is interesting for saving the machine initialization as

well as the axis position even when moving with the mains switched off.

4.3.2 - Multi-axis connection of the serial link

The parameterization of all axes is made by one single connection to the first axis via the serial link RS232. The

other axis are parameterized via the CAN bus.

4.4 - WIRING INSTRUCTIONS

According to the EN61000.4-2-3-4-5 and EN55011 standards.

4.4.1 - Motor, resolver and encoder cables

Motors, resolvers and encoders are grounded via their housing.

Cable inputs must be made by means of metal connectors with collars allowing the 360° shield connection.

The resolver cable must be pair twisted and shielded (sin, cos, ref.). Motor cables MUST also be shielded and

connected over 360° at both ends.

Encoder inputs A, B, C, D, Z and R require pair twisted and shielded cables. The shield must have a 360°

connection via metallic collars at both ends.

RS 232

Setup

monitoring

Host controller

CANopen® DS402

CAN bus

CAN bus

RT

R

T

RT = 120

Ω

terminal resistor connected between CAN-L and CAN-H lines