- Replace cooling lubricant adapter (HSK tool mountings)

Carrying out the maintenance activities described below requires

special knowledge. For this reason, these maintenance activities

must only be carried out by staff that has received adequate training

by the machine manufacturer!

Orientation

HSK tool mountings feature a so-called internal cooling lubricant supply in which the

cooling lubricant is fed through the tool to the tool’s cutting edge. To ensure a tight

connection between the tool spindle and the HSK shank when a tool is changed

(automatically or manually), there is a cooling lubricant adapter inside the HSK

shank. This adapter is spring-mounted using O-rings so it can move to some extent,

which provides for a safe tool change. As this O-ring is subjected to natural wear, it

must be replaced at regular intervals.

Procedure

1. Replace cooling lubricant adapter (also for tools inside the tool magazine).

Check the correct seating of the cooling lubricant adapter, and replace the

sealing ring at the cooling lubricant adapter.

2. Remove the tool including the HSK tool mounting.

3. Check the centric position of the cooling lubricant pipe. It should be possible to

shift the pipe approximately 1 mm from the center, after which it centers again

automatically (resilient). Otherwise the cooling lubricant pipe has to be

removed and the O-ring has to be replaced. The following steps must be

performed.

4.

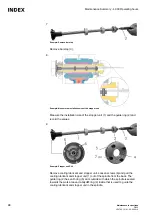

Example: Sealing at the cooling lubricant adapter

1

Groove nut

2

Cooling lubricant tube

3

O-ring

4

HSK tool mounting

Clean the tool including the HSK tool mounting before the removal.

5. Loosen and remove groove nuts (1) inside the HSK tool mounting (4) using the

supplied special tool.

6. Remove cooling lubricant pipe (2) and replace O-ring (3).

Maintenance Summary - 4.000 Operating hours

91

Maintenance Instructions

R200

LR1702.10181 - 05.06.2019