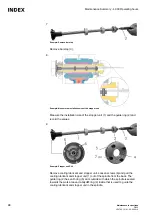

- Check and potentially replace the end position dampers

Orientation

Besides the software end positions and the emergency stop switches, the end

position dampers are another safety device to protect the machine from damage.

Their job is to absorb the impact force to the spindle bearings.

Therefore, regular inspection of the end position dampers for damage is necessary

to prevent damage to the spindle and its bearings.

Power off the machine, depressurize the hydraulic system by

opening the accumulator relief valve(s), and protect against

accidental power on.

Requirement

To replace the end position dampers on the bearing supports of the ballscrews, the

following utilities and tools are needed:

- servicing, testing and maintenance schedules/logs of the customer,

- rags for cleaning,

- various sizes of jaw and box wrenches, and Allen keys.

Depressurize the hydraulic system by opening the accumulator drain

valve (e), turn off the machine and prevent it from restarting.

Procedure

1. Check end position dampers

Alternatively, the following procedure can be used!

Replace if necessary

2.

Warning

Sudden, very rapid and violent movements of the tool

carriers or tool slides.

Crushing of fingers or whole hand up to death.

Before starting any maintenance or repair work, power off the

machine and secure it against restarting and depressurize all

fluid systems.

Maintenance Summary - 4.000 Operating hours

99

Maintenance Instructions

R200

LR1702.10181 - 05.06.2019