Laser Diode Driver LD8000

10

Ver. 1.0

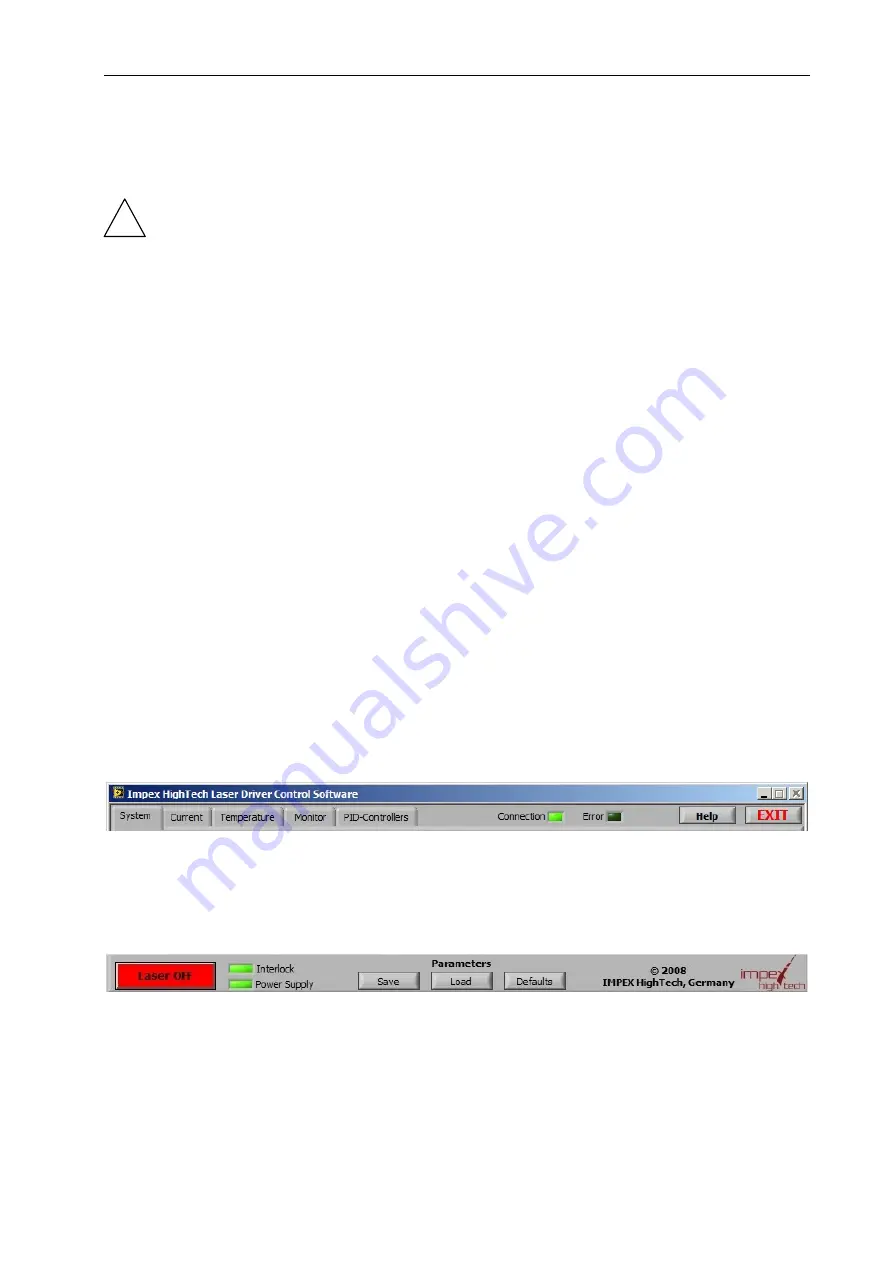

4.2 The LD Control software

The LD Control software application gives you the ability to adjust parameters quickly, to view

values on the screen and to save them to a file for documentation

Since the remote control feature qualifies to operate the laser without intervisibility,

special considerations and precausions must be met! Do not operate the laser in rooms,

where no sufficial laser safety is guaranteed! See also the chapter Interlock.

Installing LD Control (Windows)

To install LD Control software, run setup.exe from the supplied CD-ROM. This will install the

application itself and some additional runtime components. Follow the instructions of the

installer software and reboot the computer, if you will be asked to do.

Installing USB driver (Windows)

When you first time connect the LD8000 to the PC, the operating system will ask for a driver.

Select the option

“Search in other places”

and point to the folder

USB Driver\Windows

on the

CD-ROM. The device is equipped with a USB-serial converter module, so a connection to it is

made through a virtual COM Port. The number of the COM Port interface is being assigned by

the operating system automatically. To find out the corresponding COM Port number, start the

Device Manager (Start – Run... - devmgmt.msc) and look for “USB Serial Port” entry in the

Ports section, the assigned COM Port number is shown in parentheses.

Overview

Every control and indicator is equipped with online description. Get the mouse pointer over an

element for view seconds and the description will pop up.

The application is divided into five parts, represented by a card index. On the

System

card you

can setup the communication interface and some basic parameters. On

Current

and

Temperature

cards you can set all adjustable values to run the laser properly. The PID

parameters of the temperature controllers can be tuned on the

PID controllers

card. The

Monitor

card shows and logs actual values such as laser diode current and temperatures.

Right to the card tabs there are indicators for

Connection

and eventually occured

Error

. When a

connection to the device is not established (the Error indicator is lit and the Connection indicator

is dim), then the other indicators and parameters are not valid and are greyed out. See description

of the System card in such case.

Further there is a

Help

button and an

Exit

button for closing the program.

The most important element in the lower part of the user interface is the

Laser ON/OFF

button

at the bottom left corner. This button is also an indicator: when the laser is on, the button is

green, when the laser is off, the button is red.

To the right of the Laser ON/OFF button are the

Interlock

indicator, that is green, if interlock is

OK and red, if the interlock contact is broken and the

Power Supply

indicator, showing whether

the supply voltage is in the specified range (green) or not (red).

All parameters and setting can be saved to a file and loaded afterwards by the buttons

Load

and

Save

accordingly. You can also create multiple settings-files for different lasers and load them

!