32

3-1

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

A

N

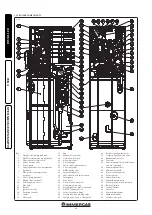

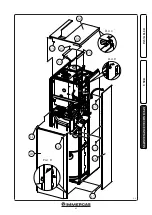

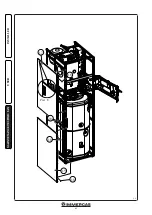

19 - Condensation module covers

20 - Condensation module

21 - Manual air vent valve

22 - Fumes hood

23 - Flue probe

24 - Air sample point

25 - Flue sample point

26 - Gas ΔP pressure point

27 - Flow probe

28 - Safety thermostat

29 - Ignition electrode

30 - Boiler Circulator

31 - System pressure switch (abso-

lute)

32 - Three-way valve (motorised)

33 - Venturi positive sign P1

34 - Venturi negative signal P2

35 - Air/gas Venturi manifold

36 - System expansion vessel

37 - Vent valve

38 - Hydraulic manifold

39 - Zone 1 pump

40 - Zone 1 one-way valve

41 - Mixing valve filter

42 - DHW mixing valve

43 - Cold water inlet cock

44 - Cold water filter

45 - Flow limiter

46 - Cold water inlet non-return

valve

47 - 8 bar safety valve

48 - DHW recirculation pump (op-

tional)

49 - Solar expansion vessel

50 - Manual air vent valve

51 - Shut-off valve with thermometer

52 - Safety valve with manometer

53 - One-way valve (OV 20)

54 - Solar pump

55 - Flow meter

56 - Solar stainless steel coil

57 - One-way valve (OV 15)

RA1 - Zone 1 system return (High

temperature)

MA1 - Zone 1 system flow (High tem-

perature)

G - Gas supply

AC - Domestic hot water outlet

AF - Domestic cold water inlet

RC - Domestic hot water recirculation

RP - Return from solar panels

MP - Flow from solar panels

SC - Condensate drain

Key

1 - Storage tank unit draining valve

2 - Magnesium anode

3 - D.H.W. expansion vessel

4 - Domestic hot water probe

5 - Stainless steel coil for storage tank

6 - System draining valve

7 - Polyphosphate dispenser (optional)

8 - System filling valve

9 - 3 bar safety valve

10 - Manifold draining valve

11 - Condensate drain trap

12 - Gas valve

13 - Gas valve outlet pressure point (P3)

14 - Air intake pipe

15 - Fan

16 - Gas nozzle

17 - Detection electrode

18 - Burner

3

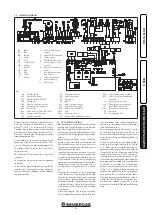

BOILER COMMISSIONING

(INITIAL CHECK)

To commission the boiler:

- make sure that the declaration of conformity

for installation is supplied with the appliance;

- make sure that the type of gas used corresponds

to boiler settings;

- check connection to a 230V-50Hz power

mains, correct L-N polarity and the earthing

connection;

- make sure the central heating system is filled

with water and that the pressure gauge indicates

a pressure of 1-1.2 bar.

- check that the the air vent valve cap is open and

that the system is well deaerated;

- switch the boiler on and check correct ignition;

- check the ∆p gas values in domestic hot water

and central heating modes;

- check the CO

2

in the fumes at maximum and

minimum flow rate;

- check activation of the safety device in the event

of no gas, as well as the relative activation time;

- check the intervention of the main switch

located upstream of the boiler and in the boiler;

- check that the intake and/or exhaust terminals

are not blocked;

- ensure activation of all adjustment devices;

- seal the gas flow rate regulation devices (if set-

tings are modified);

- check the production of domestic hot water;

- check sealing efficiency of water circuits;

- check ventilation and/or aeration of the instal-

lation room where provided.

If even only a single safety check offers a negative

result, do not commission the system.

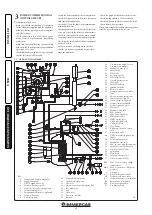

3.1 HYDRAULIC DIAGRAM.