21

1-27

1-29

1-28

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

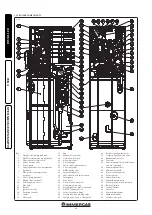

1.28 SOLAR CIRCUIT CIRCULATION

PUMP.

The units are supplied with circulating pumps

fitted with speed regulator.

These settings are suitable for most systems.

In fact, the pump is equipped with electronic

control to set advanced functions. For proper op-

eration one must select the most suitable type of

operation for the system and select a speed in the

available range, with a focus on energy savings.

Display of operation status.

During normal

operation the status LED (2) is on green (flashing

(FL) when it is in stand-by), the four yellow LEDs

(3) indicate circulator absorption according to

the following table:

Circulating pump LED

Absorption

G Y

Y

Y

Y

FL Off Off Off Off

C i r c u l a t o r i n

stand-by

G Y

Y

Y

Y

On On Off Off Off

0 ÷ 25 %

G Y

Y

Y

Y

On On On Off Off

25 ÷ 50 %

G Y

Y

Y

Y

On On On On Off

50 ÷ 75 %

G Y

Y

Y

Y

On On On On On

75 ÷ 100 %

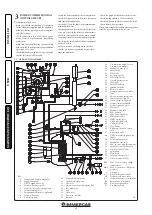

Selection of operating mode.

To see the current

operation mode it is sufficient to press button

(1) once.

To change operation mode press the button

for between 2 to 10 seconds until the current

configuration flashing, each time the button is

pressed all possible functions are scrolled cycli-

cally according to the table (Fig. 1-28). After a

few seconds without doing any operation the

circulator memorises the selected mode and goes

back to operation display.

- Constant curve: the circulator works main-

taining system head constant. The circulator

working point will move up or down according

to the system's demand.

- PWM Profile:

do not use this operation mode.

Selection button lock.

The button has a feature

that locks its operation to prevent accidental

modifications, to lock the control panel it is

necessary to press button (1) longer than 10

seconds (during which the current configuration

flashes), the active lock is signalled by all LEDs of

the control panel flashing. To unlock the button

press again longer than 10 seconds.

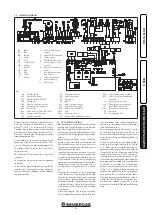

Real time diagnostics:

in the event of mal-

function the LEDs provide information on the

circulator operation status, see table (Fig. 1-29):

Circulating pump LED

Description

G Y

Y

Y

Y

On On On Off Off

Constant curve

speed 1

G Y

Y

Y

Y

On On On On Off

Constant curve

speed 2

G Y

Y

Y

Y

On On On On On

Constant curve

speed 3

G Y

Y

Y

Y

On On On Off On

Constant curve

speed 4

(de-

fault)

DO NOT USE

Circulating pump LED

Description

R Y

Y

Y

Y

On Off On Off Off

PWM Profile

speed 1

R Y

Y

Y

Y

On Off On On Off

PWM Profile

speed 2

R Y

Y

Y

Y

On Off On On On

PWM Profile

speed 3

R Y

Y

Y

Y

On Off On Off On

PWM Profile

speed 4

Key:

1 - Function selection button

2 - Green (G) / red (R) LED

3 - 4 yellow LEDs (Y)

Circulating pump LED

(first red LED)

Description

Diagnostics

Remedy

R Y

Y

Y

Y

On Off Off Off On

Circulator pump blocked

The circulator pump cannot restart

automatically due to an anomaly

Wait for the circulator to make auto-

matic release attempts or manually

release the motor shaft acting on the

screw in the centre of the head.

If the anomaly persists replace the

circulator.

R Y

Y

Y

Y

On Off Off On Off

Abnormal situation (the circulator

continues operating).

low power supply voltage

Voltage off range

Check power supply

R Y

Y

Y

Y

On Off On Off Off

Electrical fault

(Circulator pump blocked)

The circulator is locked due to power

supply too low or serious malfunction

Check the power supply, if the anomaly

persists replace the circulator