23

STEkW ed 12/06

EOLO Maior kW

Technical Documentation

Technical Documentation

Air inlet / flue exhaust kit.

The kits and their respective accessories allow to use four con-

centric pipe systems and two twin pipe systems.

In regards to pressure drops related to each accessory, the

various possible combinations and the position of the flue

shutter according to the length and type of pipes, please follow

the instructions for air inlet/flue outlets kits

(see instruction

manual of the boiler).

The connection between different accessories

(bends, extensions,

terminals)

is realized by push-fitting and the seal is provided

by special lip gaskets.

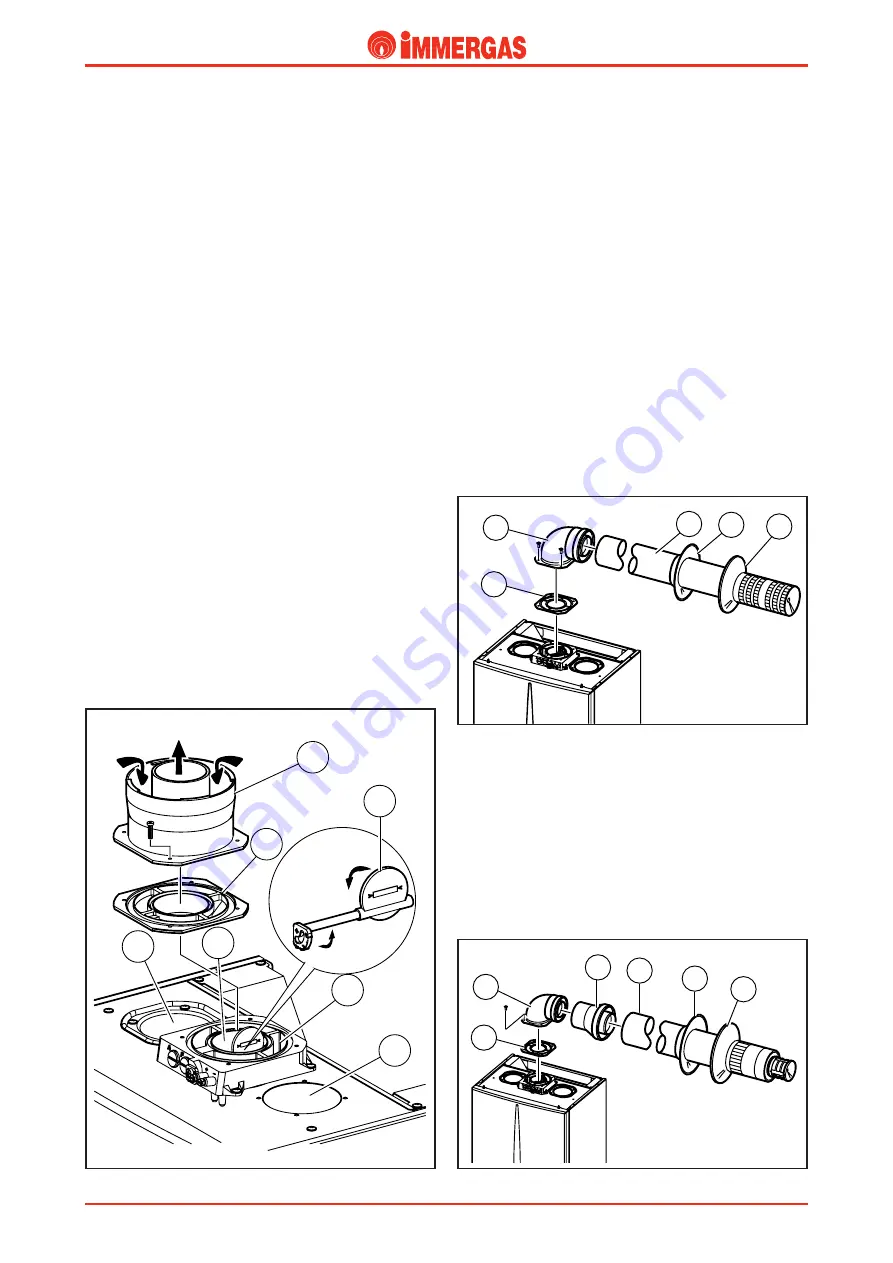

Coupling type horizontal concentric kit 60 /100.

The exhaust pipe (Ø 60 mm) is fitted inside the extraction

pipe (Ø 100 mm).

Connection to the boiler is made using a 90° curve (2) that

can be positioned in any direction and which, by means of

the necessary extensions, must be connected to the special

extraction and exhaust end (3).

Max possible overall length beyond the first curve (2) is

3

straight and horizontal metres.

1

2

5

4

3

Coupling type horizontal concentric kit 80 /125.

The exhaust pipe (Ø 80 mm) is fitted inside the extraction

pipe (Ø 125 mm).

Connection to the boiler is made using a 90° curve diameter

60/100 (2) that can be positioned in any direction and which,

by means of the adapter 60/100-80/125 (3) and necessary

extensions, must be connected to the special extraction and

exhaust end (4).

Max possible overall length beyond the first curve (2) is

7.3

straight and horizontal metres.

1

2

6

4

3

5

1

2

3

5

4

6

7

Fan-assisted, sealed chamber configuration

(type C).

Exhaust.

Connection to the exhaust pipes is by means of a flange (1) or

a flanged bend to connect to fitting (4) on top of the sealed

chamber, placing a special shaped seal in between (6).

The flange differs according to whether the split or concentric

system is used.

In the first case, the passage for the air inlet of combustion air

(5) is closed while, in the second case, it is used.

The flue shutter (7) is mounted on the exhaust fitting (4) which

has to be adjusted to ensure correct boiler operation.

The appropriate adjustment depends on the type of pipe used

and its length

(see boiler instruction handbook).

To adjust, unscrew the front stop screw and move the gradu-

ated indicator to the correct position, aligning the value to the

horizontal reference.

Air inlet.

Using the split system, connection to the air inlet pipes is

exactly the same as for the exhaust pipes, connecting to the 80

mm diameter hole (2) at the top of the sealed chamber.

The unused hole is closed with one of the caps (3) supplied

with the boiler.

If coaxial pipes are used, air inlet occurs by using the concentric

hole outside the exhaust pipe (5).

Summary of Contents for EOLO Maior kW

Page 2: ......