F64B, F64L Ultra high efficiency coalescing filter

Installation & Maintenance Instructions

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document. (1999 - I&M8076c) © 2015 IMI International s.r.o.

I&M/en 8.240.115.02

3/19

coalescing element (46, 50) will need

renewing if pressure drop becomes excessive.

It is not designed to be cleaned. Replace

carbon pack (8) with new element if

discoloured due to oil adsorption. When

replacing or renewing top element, wipe main

filter body thoroughly to remove alltraces of oil

and renew o-ring. If top element becomes

saturated with oil in a short period, the main

element or o-ring may be faulty and should

be replaced. Clean plastic bowl (31, 40) with

warm water only. Clean other parts with warm

water and soap. 2. Rinse and dry parts. Blow

out internal passages in body with clean, dry

compressed air. 3. Inspect parts. Replace

those found to be damaged. Replace plastic

bowl with a metal bowl if plastic bowl shows

signs of cracking or cloudiness.

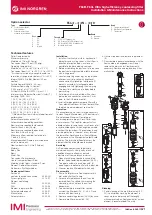

Assembly

1. Lubricate o-rings with o-ring grease.

2. Assemble the unit as shown on the exploded

view.

3. Turn bowl or bowl with guard (14, 21, 28, 37)

fully clockwise into body.

Caution

Water vapor will pass through these units and

could condense into liquid form downstream as

air temperature drops. Install an air dryer if water

condensation could have a detrimental effect on

the application.

WARNING

Polycarbonate plastic bowls can be damaged

and possibly burst if exposed to such

substances as certain solvents, strong

alkalies, compressor oils containing ester-based

additives or synthetic oils. Fumes of these

substances in contact with the polycarbonate

bowl, externally or internally, can also result in

damage. Clean with warm water only.

Use metal bowl in applications where a plastic

bowl might be exposed to substances that are

incompatible with polycarbonate.

Before using these products with fluids other

than air, for non industrial applications, or for

life-support systems consult Norgren.

Use in potentially explosive atmospheres

Code of device according EC directive

2014/34/EU

II 2G Ex h IIC T6 Gb

II 2D Ex h IIIC T85ºC Db

• Only non-flammable gasese to be used as a

medium.

• Surface temperature dependant on process

fluid temperature and ambient temperature -

must be below the ignition temperature of the

flammable gas or dust.

• Earth unit and/or pipework to avoid

electrostatic discharge.

• Precautions should be taken to prevent hazard

from adiabatic compression.

• Use wet cloth for cleaning.

• Protect the unit from object falling onto it.

• Avoid contact with corrosive environment.

• For servicing the unit it is recommended to

carry out this work outside of the danger

zone.

• For details of ignition hazard assessment

contact Norgren.

42

44

43

8

9

1

2

5

6

3

11

49

48

47

46

10

12

15

19

38

39

40

41

16

17

20

18

45

13

54

53

52

51

50

29

30

35

32

33

36

31

34

22

24

26

25

23

27

4

14

21

28

37

7