12

CLEANING AND MAINTENANCE

GREASE METAL FILTERS

These filters are usually made in aluminium or stainless

steel, and their main purpose is to block the particles of oil

and fat suspended in the cooking fumes.

An excessive accumulation of grease inside the filters

could cause unpleasant smells and decrease the suction

power of the hood. Please note that accumulated fat is

highly flammable: any fire could lead to severe damage to

both users and the product.

For these reasons, the anti-grease filters should be washed

at least

once a month

, immersing them into hot water and

dish soap for at least one hour.

Rinse with plenty of water and wait for the filters to be fully

dry before putting them back in place.

Please note that the maximum temperature is

70°C/158°F

:

higher temperature can cause darkening in the metal

(please note that this DOES NOT impair the operation of

the filter).

For their removal see

Fig. 5

.

ACTIVE CARBON FILTERS

These filters cannot be washed or regenerated, and should

therefore be replaced every 3 to 4 months, depending on

the hood usage. Damp environments, high temperature,

soiled anti-grease filters and the use of an induction hob

could result into an accelerated decay of the filters.

There are two different kind of carbon filters:

- a rectangular one (similar to the metallic anti-grease filter,

it can be removed by simply pulling the handle);

- a rounded one (usually secured to the blower, it can be

removed by counter-clockwise twisting).

For the instructions on carbon and anti-grease filters

removal, see

Fig. 6

.

Internal recirculation hoods have to be used only with

active carbon filters installed.

1

2

Fig.6

A

C

B

Summary of Contents for AGK Series

Page 2: ......

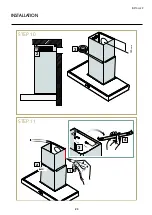

Page 19: ...19 INSTALLER STEP 3 OK 2 1 INSTALLATION ...

Page 20: ...20 STEP 4 STEP 5 1 1 ø8 mm ø 05 16 2 NON FORNITA 2 3 INSTALLATION ...

Page 21: ...21 INSTALLER STEP 6 STEP 7 1 3 4 2 2 3 1 ø8 mm ø 05 16 40 mm 137 64 INSTALLATION ...

Page 22: ...22 STEP 8 STEP 9 INSTALLATION ...

Page 23: ...23 INSTALLER INSTALLATION STEP 10 STEP 11 150 mm 3 3 4 2 1 2 ...

Page 24: ...24 INSTALLATION STEP 12 STEP 13 2 3 4 1 ø8 mm ø 05 16 40 mm 137 64 ...

Page 25: ...25 INSTALLER INSTALLATION STEP 14 1 STEP 15 2 ...

Page 26: ...26 INSTALLATION STEP 16 2 1 ...

Page 32: ......