11

USER

CLEANING AND MAINTENANCE

ƂNVTQCKECTDQPKCVVKXKUQNQ

ECRRC ƂNVTCPVG XGFGTG

ƂNVTKOGVCNNKEK

All ordinary maintenance operations must be

carried out:

• after disconnecting the electric power supply;

• always wearing appropriate personal protective equipment (e.g.: gloves, etc...).

Failure to follow the instructions, or use of unsuitable products, may pose a risk of fire

and/or damage to the equipment or other objects, for which the Manufacturer

cannot be held responsible.

• When cleaning any of the components or accessories, NEVER use:

• abrasive or powder detergents;

• aggressive or corrosive detergents (e.g. hydrochloric/muriatic or sulphuric acid).

• abrasive or sharp tools (e.g. abrasive sponges, scrapers, steel brushes, etc.);

• water sprays

The INSIDE and the OUTSIDE of the hood should be cleaned solely by using a damp

cloth with little neutral soap. It is also possible to use a steel specific cleanser, paying

attention to the instructions written on the canister or bottle.

To conclude the cleaning operation, rinse using a clean wet sponge or cloth and then

use a rag to dry the surface (in case of satin steel, please rub according to the finish

pattern).

Please follow the instructions stated above for metal surfaces.

STAINLESS STEEL AND OTHER

METAL SURFACES

CONTROL PANEL

activated carbon filter (filtering/

internal recirculation cooker

hood only) see Fig. 2.

anti-grease metal filter

Fig.4

Summary of Contents for AGK Series

Page 2: ......

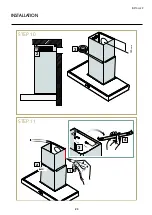

Page 19: ...19 INSTALLER STEP 3 OK 2 1 INSTALLATION ...

Page 20: ...20 STEP 4 STEP 5 1 1 ø8 mm ø 05 16 2 NON FORNITA 2 3 INSTALLATION ...

Page 21: ...21 INSTALLER STEP 6 STEP 7 1 3 4 2 2 3 1 ø8 mm ø 05 16 40 mm 137 64 INSTALLATION ...

Page 22: ...22 STEP 8 STEP 9 INSTALLATION ...

Page 23: ...23 INSTALLER INSTALLATION STEP 10 STEP 11 150 mm 3 3 4 2 1 2 ...

Page 24: ...24 INSTALLATION STEP 12 STEP 13 2 3 4 1 ø8 mm ø 05 16 40 mm 137 64 ...

Page 25: ...25 INSTALLER INSTALLATION STEP 14 1 STEP 15 2 ...

Page 26: ...26 INSTALLATION STEP 16 2 1 ...

Page 32: ......