-8-

www.igmtools.com

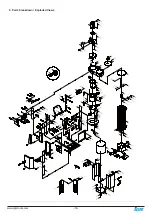

Step 14. Move HEPA filter assembly under the dust chute, and with the

help of another person holding the HEPA filter, secure the top end of the

rotation shaft to the cleaning spindle inside the dust chute using (1) 5/16”

x 1-1/2” hex bolt, (2) 5/16” x OD18 x 2t flat washers and (1) 5/16” lock nut.

Step 15. Open the canister filter shield and secure the HEPA canister filter

onto the dust chute by fastening the band clamp on the top part of the

HEPA canister filter. Make sure the band clamp is tightly fastened. It does

not matter which side the clamp faces.

Step 16. Attach the canister filter end cap to the canister filter using the (4)

latches. Cover the 4” hook up with the 4” rubber plug.

Step 17. Secure the lower triangular support plate to the base using (2)

5/16”*3/4” hex bolts and (2) 5/16”*OD18*2t flat washers. Follow the same

steps for the opposite side.

Step 18. Locate the two foot pedal bars provided. There is a left side and

right side. To identify the correct side, look for the protruding nut, circled

in red below. It should be facing upwards when you place the bars on the

floor.

Step 19. Ensure that the foot pedal bar is the correct side and slide the

Foot pedal bar into the opening on the lower upright support panel. Make

sure the end of the bar is on the inside of the triangular support plate.

Follow the same steps for the opposite side.

Step 20. Secure the top end of the foot pedal bar to support bracket using

(4) 5/16”*1-3/4” hex bolts, (8)5/16”*OD18*2t flat washers and (4) 5/16” hex

nuts. Make sure the foot pedal bar is pushed all the way to the end of the

support bracket (indicated by yellow arrows). Follow the same steps for

the opposite side.

Step 21. Secure the base of the foot pedal bar to the triangular support

plate by holding the lower support plate vertically up against the foot pedal

bar and securing the U channel provided onto the foot pedal bar using

(2)5/16”*1-3/4” hex bolts, (4) 5/16”*OD18*2t flat washers and (2) 5/16” hex

nuts from the inside out. Follow the same steps for the opposite side.

Step 22. Attach the cover plate over the foot pedal assembly. Secure

using (6) 1/4”*3/4” hex bolts and (6) 1/4”*OD19*2t flat washers. Follow the

same steps for the opposite side.