-3-

www.igmtools.com

Contents

1. Declaration of conformity

1.1 Warranty

2. PFlux3 Specifications

3. General Safety Rules and Instructions

3.1 Important Safety Instructions

3.2 General Rules

3.3 Additional Safety Intructions

3.4 Power Supply

3.5 Motor Specifications

3.6 Grounding Instructions

4. Parts Description

4.1 Functions

5. Assembly

6.1 Unpacking

6.2 Assembling the Unit

6. Maintenance

7. Troubleshooting

8. Power connection and wiring diagram

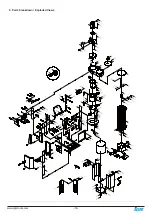

9. Parts breakdown / Exploded Views

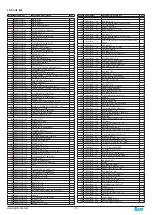

10. Parts list

1. Declaration of conformity

We declare that this product is in compliance with the directive and the

standard mentioned on the previous page of this manual.

1.1 Warranty

IGM Tools & Machinery strives to always deliver high-quality machinery.

The warranty is governed by the valid terms and conditions of IGM Tools &

Machinery available at www.igmtools.com.

2.

Specifications

Motor

2200 W

Power 400V / 50Hz / 3 HP

Recommended Breaker

Size 16 A, tripping characteristic C (16/3/C)

Airflow (traditional method)

3831 m

3

/hour (2253 CFM)

Airflow (realistic method)

2209 m

3

/hour (1299 CFM)

Max. Static Pressure

285 mm in water

Fan Diameter

390 mm

Inlet Diameter

1x 200 mm nebo 3 x 100 mm

Switch

High frequency remote control switch

Noise

76 dB(A) na 3 m

Drum Collection

174 l, octagonal drum

Packing Size (LxWxH)

1300 x 800 x 1300 mm

Weight

175 kg

Shipping Weight

200 kg

Filter

Filtering Area:

9,5 m

2

Cartridge Filter diameter

400 mm x height 900 mm

Filtration Size

HEPA - 99.2 %, 0.4 Micron

Drum Collection Bag Layflat Size

960 x 1200 mm

3. General Safety Rules and Instructions

3.1 Important Safety Instructions

Read and understand all warnings and operating instructions before using

this equipment. Failure to follow all instructions listed below, may result in

electric shock, fire, and/or serious personal injury or property damage.

Woodworking can be dangerous if safe and proper operating procedures

are not followed. As with all machinery, there are certain hazards involved

with the operation of the product. Using the machine with respect and

caution will considerably lessen the possibility of personal injury. However,

if normal safety precautions are overlooked or ignored, personal injury

to the operator may result. Safety equipment such as guards, push

sticks, hold-downs, feather boards, goggles, dust masks and hearing

protection can reduce your potential for injury. But even the best guard

won’t make up for poor judgment, carelessness or inattention. Always use

common sense and exercise caution in the workshop. If a procedure feels

dangerous, don’t try it. Figure out an alternative procedure that feels safer.

REMEMBER: Your personal safety is your responsibility.

This machine was designed for certain applications only. We strongly

recommend that this machine not be modified and/or used for any

application other than that for which it was designed. If you have any

questions relative to a particular application, do not use the machine until

you have first contacted the manufacturer to determine if it can or should

be performed on the product.

If you have any questions relative to its application do not use the product

until you have contacted the manufacturer and we have advised you.

When using an electrical appliance, basic precautions should always be

followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING (THIS APPLIANCE)

To reduce the risk of fire, electric shock, or injury:

• Do not leave appliance when plugged in. Unplug from outlet when not in

use and before servicing.

• Do not use outdoors or on wet surfaces.

• Do not allow to be used as a toy. Close attention is necessary when

used by or near children.

• Use only as described in this manual. Use only manufacturer’s

recommended attachments.

• Do not use with damaged cord or plug. If appliance is not working as it

should, has been dropped, damaged, left outdoors, or dropped into water,

return it to a service centre.

• Do not pull or carry by cord, use cord as a handle, close a door on cord,

or pull cord around sharp edges or corners. Do not run appliance over

cord. Keep cord away from heated surfaces.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Do not handle plug or appliance with wet hands.

• Do not put any object into openings. Do not use with any opening

blocked; keep free of dust, lint, hair, and anything that may reduce air flow.

• Keep hair, loose clothing, fingers, and all parts of body away from

openings and moving parts.

• Turn off all controls before unplugging.

• Use extra care when cleaning on stairs.

EN - English

Operating Instructions

(translation of the original instructions)

Dear Woodworker,

Thank you for your purchase and welcome to the Laguna Tools group of discerning woodworkers. We understand that you have a

choice of where to purchase your machines and appreciate the confidence you have in the Laguna Tools brand.

Every machine manufactured by Laguna Tools has been carefully designed and well thought through from a woodworker’s perspective.

Through hands-on experience, Laguna Tools is constantly working hard to make innovative, precision products. Products that inspire

you to create works of art, are a joy to run and work on, and encourage your performance.