www.igmtools.com

5

Operating manual EN

5.3 Connection to power

Before connecting the machine to electricity

network, make sure that the main switch is in the ‘0’

OFF (turned off) position.

The plug, as well as the cable must meet standards.

Line voltage must be consistent with the label on the

power tool. Wiring and repairs of electrical parts may

be carried out only by a qualified electrician.

5.4 Dust Extraction

The trimmer has to be connected to an industrial dust

extractor before use. To connect, use the extraction

outlet (Note 6) Use a 25,4mm diameter hose. Some

shavings may be charged with static electricity and

remain “stuck” to material or power tool.

We recommend using a 2,5m

3

/s suction power.

Turn on the exhaustion before starting the machine

6. PREPARATION FOR OPERATION

Before operation, make sure the workpiece is firmly

stationed.

Connect the dust extraction to the outlet.

Check if the rotation of the power tool does not

exceed the limit of the router bit.

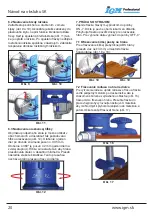

6.1 Assembly of the Trimmer

First separate the motor and the trimmer. Completely

unscrew the quick release lever and remove it. Now,

by pulling down you can remove the motor from the

trimmer.

fig. 2

Select the adequate tool for trimming. Use 22mm and

13mm wrenches to release the hex nut (fig.3). Based

on the selected router/cutter, choose a suitable collet

(6mm or 8mm). Make sure the collet and router bit are

clean and are not damaged. Now affix it to the power

tool (fig.4). Make sure the router bit is correctly placed

into the collet and is sufficiently pushed in according

to the mark on the arbor. Improper assembly may

cause danger in the form of vibration, or tool release.

Do not tighten the union bit, if the router bit is not

inserted, you will prevent damage to the collet. Use

22mm and 13mm wrenches to tighten the hex nut

and make sure it is thoroughly affixed (fig.5).

fig. 3

fig. 4

fig. 5

fig. 6

When the bit is installed, re-insert the support table

onto the motor in the arrow direction (fig.6). Put back

the quick release lever and tighten the nut. Adjust

the height of the supporting table on the body of

the motor (fig.7). Tighten the quick release lever in

the arrow direction (fig.8). to lock it. The supplied R2

radius router bit is ideal for a 2mm edge. The router

bit radius should match the thickness of the edge.

1.

2.

3.

fig. 7

fig. 8