Mechanical Air & Vapor Eliminators

33

Get the latest PDF manual:

https://www.lcmeter.com/resources/technical/manuals

Mobile/online version of this manual:

https://www.lcmeter.com/manuals

Relieving Internal Pressure

Be sure to relieve internal pressure and remove all product from the system before

disassembling the mechanical air eliminator. See the warning above.

Replace the Valve Plates & Cover Gaskets

Follow these steps:

1. Remove the cover screws from the air eliminator cover with a 1/2-inch wrench or socket.

Then pull the cover, vent plate, and seal ring from the housing.

2. Inspect the raised ridge of the vent port opening in the middle of the valve plate for

marring or debris. Inspect the seal ring for damage.

3. Replace the seal ring and/or valve plate. Tighten the cover screws to a torque of 17.5 -

20.5 ft-lbs.

Replace the Reed Strips & Float Assemblies

Follow these steps:

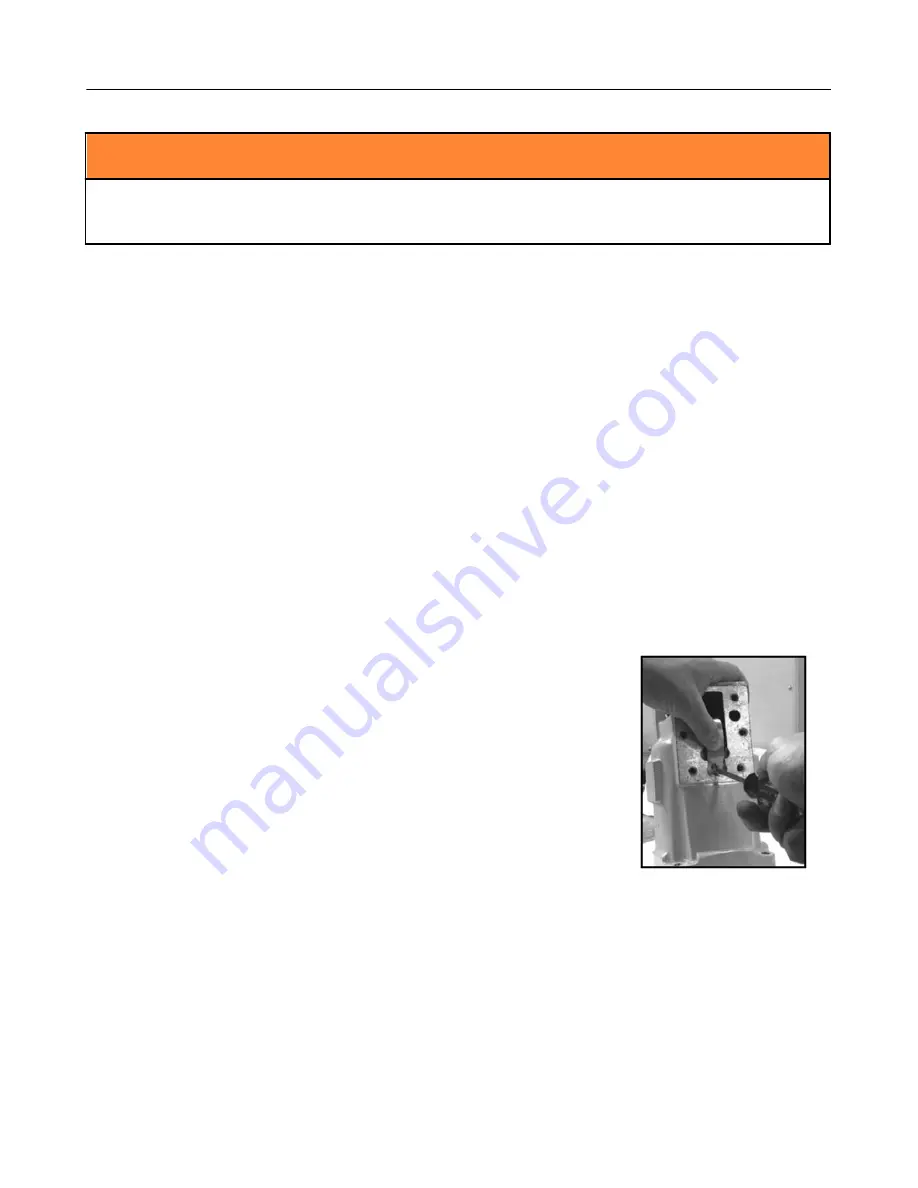

1. Remove the 4 screws and washers at the base of the air

eliminator. Pull the air eliminator off the strainer.

2. Remove the baffle plate and the baffle cup (aluminum air

eliminators only) from the housing. If the air eliminator has a

lock nut and a bushing on the bottom of the guide post,

remove them.

3. Remove the cover screws from the air eliminator cover with a

1/2-inch wrench or socket, Then pull the cover, vent plate and

seal ring from the housing.

4. To remove a reed strip that is still intact, hold down the reed

strip and unscrew the reed screw (shown on the top right).

Gently allow the reed strip to straighten. Reed strips violently

snap back if they are not held down while removing the reed

screw. Failure to hold down the reed strip could result in

injury and is the cause of many lost screws.