66

HS5E-K Interlock Switches with Key

Safety Precautions

•

In order to avoid electric shock or fire, turn the power off

before installation, removal, wire connection, maintenance,

or inspection of the interlock switch .

•

If relays are used in the circuit between the interlock

switch and the load, consider the danger and use safety

relays, since welding or sticking contacts of standard

relays may invalidate the functions of the interlock switch .

Perform a risk assessment and establish a safety circuit

that satisfies the requirement of the safety category .

•

Do not place a PLC in the circuit between the interlock

switch and the load . Safety and security can be endan-

gered in the event of a malfunction of the PLC .

•

Do not disassemble or modify the interlock switch, other-

wise a breakdown or an accident may occur .

•

Do not install the actuator in a location where the human

body may come in contact . Otherwise injury may occur .

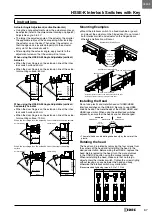

Instructions

•

Regardless of door types, do not use the interlock switch

as a door stop . Install a mechanical door stop at the end of

the door to protect the interlock switch against excessive

force .

•

Do not apply excessive shock to the interlock switch when

opening or closing the door . A shock to the interlock switch

exceeding 1,000 m/s

2

may cause damage to the interlock

switch .

•

If the operating atmosphere is contaminated, use a pro-

tective cover to prevent the entry of foreign objects into

the interlock switch through the actuator entry slots . Entry

of foreign objects into the interlock switch may affect the

mechanism of the interlock switch and cause a break-

down .

•

Using the slot plugs supplied with the interlock switch,

plug the unused actuator entry slots .

•

Do not store the interlock switches in a dusty, humid, or

organic-gas atmosphere .

•

Use proprietary actuators only . Using other actuators may

damage the interlock switch .

•

Do not modify the actuator, otherwise it will damage the

interlock switch .

•

Do not open the lid of the interlock switch . Loosening the

screws may damage the interlock switch .

•

The actuator retention force is 1,400N . Do not apply a load

higher than the rated value . When a higher load is ex-

pected, provide an additional system consisting of another

interlock switch without lock (such as the HS5D/HS5B

interlock switch) or a sensor to detect the door opening

and stop the machine .

•

Regardless of door types, do not use the interlock switch

as a door lock . Install a separate lock using a latch or take

other measures .

•

Although the HS9Z-A51A and HS9Z-A52A actuators (w/

rubber bushings) alleviate the shock when the actuator en-

ters the slot on the interlock switch, make sure that exces-

sive shock is not applied . If the rubber bushings become

deformed or cracked, replace with new ones .

•

Do not mount the interlock switch facing down as shown

in the figure below . Otherwise, the key may fall off due to

shock .

Incorrect Orientation

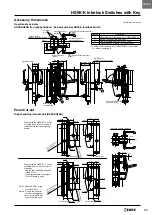

Minimum Radius of Hinged Door

When using the interlock switch for a hinged door, refer to

the minimum radius of doors shown below . For doors

with a small minimum radius, use angle adjustable

actuators (HS9Z-A53 or HS9Z-A55) .

Note: Because deviation or dislocation of a hinged door may occur in actual

applications, make sure of the correct operation before installation .

HS9Z-A52 Actuator

When the door hinge is on the extension line of the interlock switch surface:

Door Hinge

Door Hinge

(161)

(35)

Interlock Switch

Mounting Hole

(36.2)

190 mm

170 mm

Minimum Radius

M

inim

um

Radius

When the door hinge is on the extension line of the actuator mounting

surface:

(231)

(41.5)

(40.3)

230 mm

260 mm

Door Hinge

Door Hinge

Interlock Switch

Mounting Hole

Minimum Radius

Minimum

Radius

HS9Z-A52A Actuator (with rubber bushings)

When the door hinge is on the extension line of the interlock switch surface:

(35)

(36.2)

(111)

M

inim

um

Radius

Centers 12 mm :

120 mm

Centers 20 mm:

170 mm

Minimum Radius

140 mm

Door Hinge

Door Hinge

Interlock Switch

Mounting Hole

When the door hinge is on the extension line of the actuator mounting

surface:

(47)

(48.2)

(231)

260 mm

Door Hinge

Door Hinge

Interlock Switch

Mounting Hole

Minimum Radius

Minimum Radius

Centers 12 mm:

230 mm

Centers 20 mm:

310 mm