Power ON

With Start Switch

Output

Emergency Stop Switch (NC1)

➀

➀

When monitoring the start switch,

with Y3-Y5 jumpered

(default setting/recommended)

Operation

ON

Tv = 0 to 30 seconds

adjustable

OFF

➁

When monitoring the start switch,

with Y3-Y4 jumpered

➁

Emergency Stop Switch (NC2)

Output 13-14 (NO)

Output 23-24

(

NO

)

Output 57-58 (NO

)

Output 67-68 (NO

)

Output 77-78 (NO

)

Start Switch

Start Switch

Start Switch

External Start Conditions

Transistor Output Y89 (S12)

Transistor Output Y89 (S12)

Transistor Output Y90 (S22)

Transistor Output Y90 (S22)

Transistor Output Y88 (A1/A2

)

Transistor Output Y91 (Stop1)

Start

Emergency Stop

Not Operated

Emergency Stop

Operated

Without Start Switch

Emergency Stop Switch

(NC2 or NC1)

Emergency Stop Switch

(NC1 or NC2)

tmax.= 75ms

∗

➂

➂

Without start switch,

with Y3-Y4 and S33-Y1 jumpered

∗

When using without start switch,

the input synchronization time

should be 75 ms max.

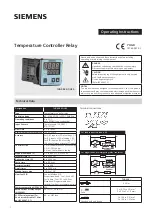

HR1S-ATE Operation Chart

Residual Risk

(

EN ISO/ISO12100-1

)

The wiring diagrams on previous page have been tested under actual oper-

ating conditions. The HR1S-ATE safety relay module can be used in a safety

circuit by connecting to safety equipment compliant to applicable standards.

Consider residual risk in the following circumstances:

a) When it is necessary to modify the recommended circuit and if added/

modified components are not properly integrated into the control circuit.

b) When applicable standards of machine operation are not observed, or

when the machine is not adjusted or maintained properly (adhere to a

strict maintenance schedule).

c) When the contacts of relays and contactors for connected with safety

outputs are not forced guided (compliant with EN 50205).

Instructions

Only persons with technical expertise may install, startup, modify, or

•

retrofit the HR1S-ATE safety relay module.

Turn the power off before installation, removal, wiring, maintenance, or

•

inspection of the safety relay module. If an error occurs, line voltage may

be present at the control circuit in devices without DC isolation.

Observe all electrical safety regulations issued by appropriate technical

•

authorities or trade association. The safety function can be lost if the

device is not used for its intended purpose.

Do not open the housing or perform invalid operation, otherwise the war-

•

ranty will become voided.

Negligence to observe the following instructions may cause accidents

•

that may result in death or serious injuries.

Connect the wires according to the wiring diagrams shown on previous

⋅

page.

Connect the wires according to applicable standards.

⋅

The contacts of relays and contactors to connected with safety outputs

⋅

must be forced guided (compliant with EN 50205).

For external fusing, use an appropriate fuse size and connect according

⋅

to the wiring diagram on previous page.

When maintaining or adjusting machines, observe the maintenance

⋅

schedule.

If the recommended circuit is modified or if components are added/modi-

⋅

fied, make sure that they are properly integrated into the control circuit.

Relays must have mechanically-linked contacts.

⋅

Follow required standards applicable to the operation of the machine.

⋅

When maintaining or adjusting machines, observe a proper maintenance

schedule.

Do not use the module if it has been subjected to improper or incorrect

•

use. In this case, the warranty will be voided.

Do not use the HR1S-ATE in conditions where irregular voltage, current,

•

temperature, or humidity could occur.

Before starting up your equipment for the first time, be sure to check all

•

safety functions according to regulations and observe the specified test

cycles for safety equipment.

Perform the following precautionary steps prior to installation, assembly,

•

or disassembly of the system.

1. Disconnect the supply voltage to the equipment / system prior to

starting work.

2. To prevent accidental activation of the module or system, perform

lock-out or tag-out.

3. Make sure that no voltage is applied.

4. Ground N (–) as shown in the wiring diagram on previous page.

5. Use guards or barriers to protect against components operating

adjacent to the safety relay module.

6. The devices must be installed in a cabinet with a protection class of

at least IP54.

Contact Protection

•

Type of protection according to EN/IEC 60529

Housing / Teminals: IP40 / IP20

Finger-safe protection according to EN 50274

Connect external fuse according to the wiring diagram on page 3.

•

Output Contact Electrical Life

(Safety Circuit, Time-delay Circuit, Auxiliary Circuit)

Operating Current × 0.1A

Operations

AC15:

230V

AC1:

230V

DC1: 24V

DC13: 24V

(<0,1Hz)

IDEC Corporation

•

1175 Elko Drive

•

Sunnyvale, CA 94089

•

800-262-IDEC (4332)

•

Fax: 408-745-5258

•

www.IDEC.com/usa

©2011 IDEC Corporation. All Rights Reserved. 06/11

PDF only.

Specifications and other descriptions in this document are subject to change without notice.