INSTALLATION AND SERVICE INSTRUCTION

Siemens Industry, Inc.

1

SD62

Rev 11

March 2011

Supersedes Rev 10

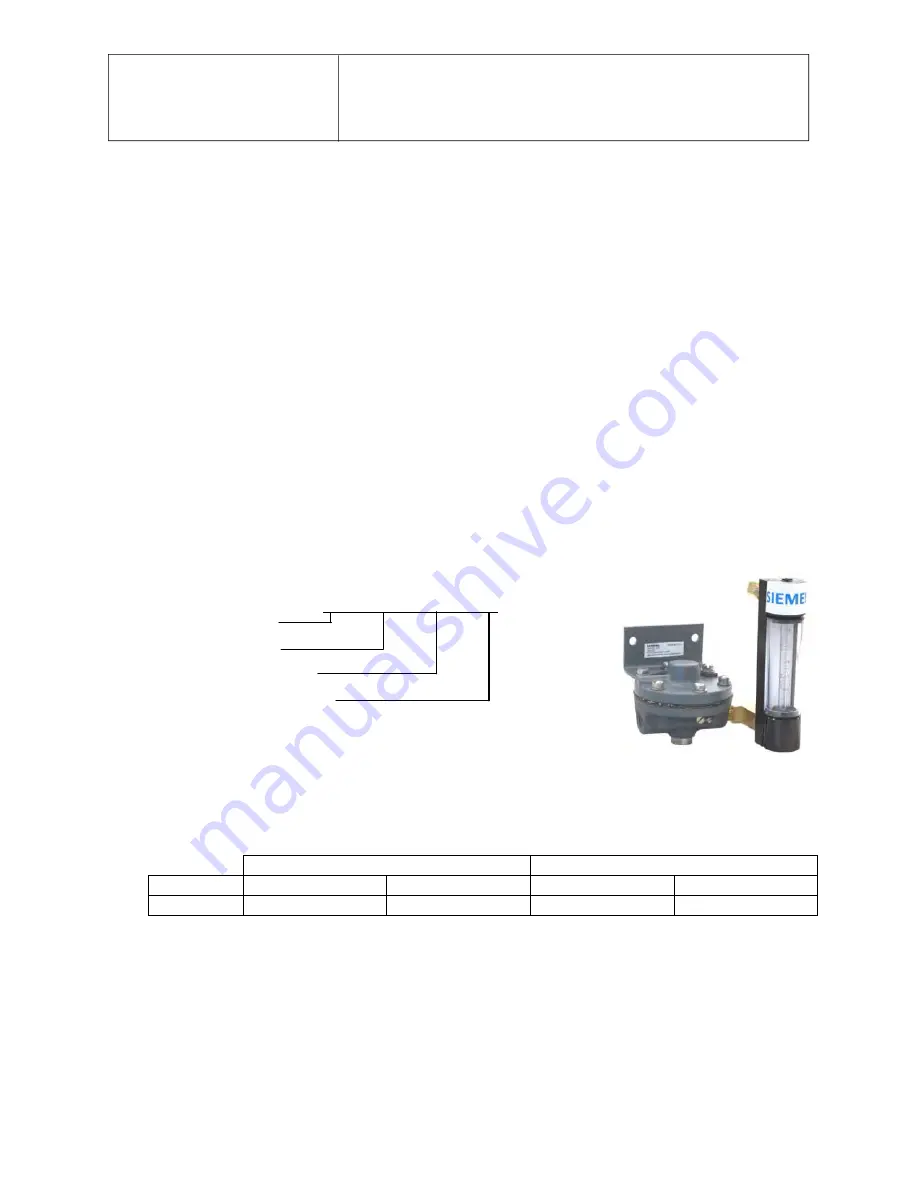

Model Series 62 Constant Differential Relay

INTRODUCTION

The Constant Differential Relay maintains a constant pressure drop across an internal needle valve for any flow

setting up to about 2.1 cubic feet of air per hour. It thus provides a means for maintaining a practically constant

volumetric rate of flow regardless of variations of the process or supply pressures. The differential maintained across

the needle valve is 1 to 2 psig. This permits a greater opening of the needle valve, thus making it less subject to

clogging. The constant differential relay may be used in conjunction with a rotameter type indicator.

The differential applied to the internal needle valve is determined by a spring-loaded diaphragm in the constant

differential relay. This diaphragm controls the action of a valve plunger to automatically admit supply air to the

needle valve at the required rate. A self-contained automatic bleed discharges excess supply air to the atmosphere

when necessary. The constant differential relay is made of aluminum, brass, stainless steel, Neoprene and Buna-N.

The rotameter is constructed of aluminum, stainless steel, borosilicate glass, Buna-N (O-rings), ruby sapphire (float)

and brass (fittings). Neither will be affected by ordinary air line impurities.

This instruction has five major sections: Introduction, Installation, Operation, Maintenance, and Parts List.

Model Designation

62

V

N

A

Constant Differential Relay

With Built-In Needle Valve

Needle Valve with Tight Shut-Off

Attached Rotameter Piped Assembly

Specifications

Supply Pressure

Minimum................................. At least 5 psig greater than the maximum downstream pressure.

Maximum ................................ 150

psig

Purge Rate:

Models 62V & 62VA

Models 62VN & 62VNA

Maximum

2.1 SCFH

991 SCCM

1.8 SCFH

850 SCCM

Minimum

0.9 SCFH

425 SCCM

0.06 SCFH

28 SCCM

Ambient Temperature Limits ................ -40° to +180°F (-40° to +82°C)