1

GENERAL

1.1 INTRODUCTION

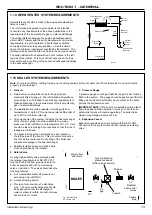

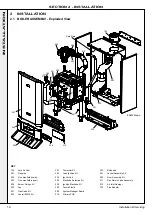

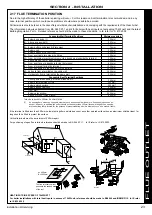

The boilers are fully automatically controlled, wall mounted,

fanned, super efficient condensing appliances.

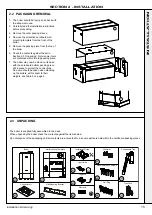

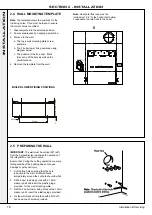

The condensing boilers can be installed either on the wall or into

a prefabricated floor mounted frame.

The boilers are suitable for use with a room sealed flue or open

flue application.

Through a sophisticated control system combined with premix

burner arrangement the boilers are capable of high seasonal

efficiencies of >96% and low emissions.

These boilers are fitted with an integral flue non-return valve

which negates the fitting of same in shared flue (B23) systems.

These boilers are certified to meet the requirements of the EC

Gas Appliance Directive, Boiler Efficiency Directive, EMC and

Low Voltage Directive.

Note.

These boilers cannot be used on systems that include

gravity circulation.

The boiler are suitable for connection to fully pumped, open

vented or sealed water systems. Adequate arrangements for

completely draining the system by provision of drain cocks MUST

be provided in the installation pipework.

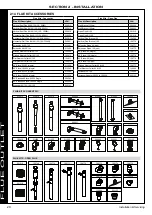

1.2 OPTIONAL EXTRA KITS

•

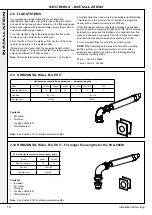

External Vertical Terminal Extension Kit 80/125

•

External Vertical Terminal Extension Kit 100/150

•

Vertical Roof Flue Kit 80/125

•

Vertical Roof Flue Kit 100/150

•

Horizontal Wall Flue Kit 80/125

•

Horizontal Wall Flue Kit 100/150

•

Open Flue Kit 80

•

Open Flue Kit 100

•

Cascade Flue Kit

•

Plume kit

•

Pitched and flat weather collars

•

90º Extended Elbow 80/125 Single

•

90º Extended Elbow 100/150 Single

•

Expander 80/125 - 100/150

System

•

Frame and Header Kits & accessories

•

Pump kits

Controls

•

Outside temperature sensor

•

DHW tank sensor/Flow sensor/Header sensor. Pocket version

•

DHW tank sensor/Flow sensor/Header sensor. Strap-on version

•

Room temperature sensor

•

OpenTherm room control

•

0-10V Pump control kit

•

Safety interlock kit

•

Cascade, first boiler

•

Cascade, subsequent boiler

•

Extension module

•

Modulating sequencer kit

•

Sequencer, OpenTherm room control

•

6 relay zone expansion kit

•

Sequencer and zone expansion pocket sensor, DHW or flow temp

•

RDG, remote diagnostic gateway

•

OpenTherm to Modbus gateway

•

OpenTherm to BACnet gateway

•

OpenTherm to LONworks gateway

•

OpenTherm to KNX gateway

Fuel

•

Propane to Natural Gas Conversion Kit

Please note propane variants of the boiler are Cat II

2H3P

(20/37) and

may be converted to natural gas operation only using the approved

conversion kit. Natural gas variants of the Boiler are Cat I

2H

and

cannot be converted to propane operation.

1.3 SAFETY

Current Gas Safety (Installation and Use) Regulations

or rules in force

The appliance is suitable only for installation in GB and IE and

should be installed in accordance with the rules in force.

In GB, the installation must be carried out by a suitably qualified

Gas Safe registered engineer or in IE by a competent person. It

must be carried out in accordance with the relevant requirements

of the:

•

Gas Safety (Installation and Use) Regulations

•

The appropriate Building Regulations either The Building

Regulations, The Building Regulations (Scotland), Building

Regulations (Northern Ireland).

•

The Water Fittings Regulations or Water byelaws in Scotland.

•

The Current I.E.T. Wiring Regulations.

Where no specific instructions are given, reference should be

made to the relevant British Standard Code of Practice.

In IE, the installation must be carried out by a Competent Person and

installed in accordance with the current edition of I.S.813 “Domestic

Gas Installations” or I.S. 820 “Non-Domestic Gas Installations” as

appropriate, the current Building Regulations and reference should

be made to the current ETCI rules for electrical installation.

The Boiler boilers have been tested and certified to;

BSEN 15502-1, BSEN 15502-2, BSEN 15502-2-1, BSEN 60335-1,

BSEN 60335-1, BSEN 60335-2-102, BSEN 55014-1 and BSEN

55014-2 for use with Natural Gas & Propane.

Detailed recommendations are contained in the following Codes

of Practice:

BS. 6891

Installation of low pressure gas pipework of up to

28mm (R1) in domestic premises (2nd family gas).

BS. 5440

Inst. and maintenance of flues and ventilation for

gas appliances of rated input not exceeding 70kW

net (1st, 2nd and 3rd family gases).

Part 1

Specification for installation of flues.

Part 2

Specification for installation and maintenance of

ventilation for gas appliances.

BS. 6644 : 2011 Installation of gas fired hot water boilers of rated

inputs between 70kW and 1.8MW (net) (2nd

and 3rd family gases).

BS. 6798

Installation and maintenance of gas fired hot water

boilers of rated input not exceeding 70kW net.

BS. 6880

Low temperature hot water heating systems of

output greater than 45kW.

Part 1 Fundamental and design considerations.

Part 2 Selection of equipment.

Part 3 Installation, commissioning and maintenance.

BSEN.12828:2012 Heating Systems in buildings: Design for water

based systems.

BSEN.12831:2017 Heating Systems in buildings: Method for

calculation of the design heat load.

BSEN.13831

Specification for: Expansion vessels using an

internal diaphragm, for sealed hot water heating

systems.

BSEN.14336:2004 Heating Systems in buildings: Installation and

commissioning of water based heating systems.

IGEM/UP/1

Soundness testing and purging of industrial and

commercial gas installation.

IGEM/UP/2

Gas installation pipework, boosters and

compressors on industrial and commercial

premises.

IGEM/UP/10

Installation of gas appliances in industrial and

commercial premises.

8

Installation & Servicing

SECTION 1 - GENERAL

Summary of Contents for EVOMAX 2 30

Page 4: ...4 Installation Servicing...

Page 75: ...75 Installation Servicing NOTES...

Page 76: ...76 Installation Servicing NOTES...

Page 77: ...77 Installation Servicing NOTES...

Page 78: ...78 Installation Servicing NOTES...