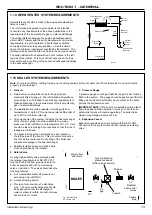

2.20 BOILER WATER CONNECTIONS

The boiler flow and return pipes are

terminated with a 1

1

/

4

” BSP male taper

connection located at the bottom of the

appliance.

Note.

This appliance is NOT suitable for use

with a direct hot water cylinder.

Plastic plugs if fitted into the open ends of

the flow and return pipes must be removed

before connecting the system pipework.

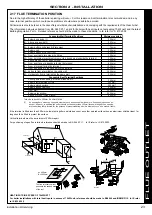

2.21 FROST PROTECTION

The boiler has built into its control system the facility to protect

the boiler, only against freezing.

If the boiler flow temperature T

1

, falls below 5

o

C the pump and

burner run until the temperature exceeds 19

o

C.

Central heating systems fitted wholly inside the building do

not normally require frost protections as the building acts as

a ‘storage heater’ and can normally be left at least 24 hours

without frost damage. However, if parts of the pipework run

outside the building or if the boiler will be left off for more than

a day or so, then a frost thermostat should be wired into the

system.

FLOW

RETURN

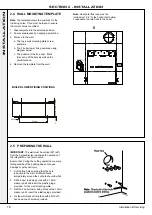

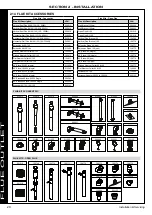

2.22 GAS CONNECTION

Refer to Section 1.13 for details of the position of

the gas connection.

A MINIMUM working gas pressure of 17.5 mbar

(7” w.g.) must be available at the boiler inlet for

natural gas and minimum of 32mbar for propane

with the boiler firing. Refer to Section 3.3 for

details of the pressure test point position.

Extend a gas supply pipe NOT LESS THAN 22mm

O.D. to the boiler and connect using the gas cock

provided.

IMPORTANT

. The gas service cock contains a

non-metallic seal so must not be overheated when

making capillary connections.

The pressure loss for LPG versions is negligible due to the very low

velocity through the pipe work.

Note.

It should be noted that this pressure drop is present within the

internal boiler pipe work and is irrespective of the fact that manifold

headers are used. This pressure drop will be experienced on each

individual boiler regardless of single or multiple installation.

In order to determine the actual working gas pressure at the

boiler inlet the figure from the table below must be added to the

measured pressure (refer to Section 3.3).

Gas Line Pressure Drop

(Natural Gas)

Boiler Model

mbar

30

0.6

40

0.8

60

1.4

80

1.6

100

1.1

120

2.7

150

3.0

27

Installation & Servicing

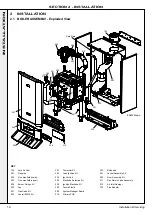

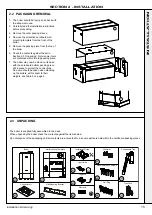

SECTION 2 - INSTALLATION

INST

ALLA

TION

Summary of Contents for EVOMAX 2 30

Page 4: ...4 Installation Servicing...

Page 75: ...75 Installation Servicing NOTES...

Page 76: ...76 Installation Servicing NOTES...

Page 77: ...77 Installation Servicing NOTES...

Page 78: ...78 Installation Servicing NOTES...