Page

Installation instructions 3

List of Warnings 4

Operation 5

Maintenance 6

Parts Drawing 7

Parts List 8

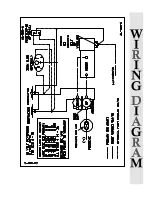

Wiring 9

Warranty 10

Anchor windlass

Hawse pipe/chain stripper

Windlass cover

Footswitches

Solenoids

Circuit breaker

Instructions

Electric drill

17/32 drill bit

2” hole saw

Jig saw

Wrench set

Screwdrivers

Caulking & gun

Grease

Mounting bolts for the windlass base, four 3/8 bolts

Mounting bolts for the chain stripper/ hawse pipe, four 1/4 bolts

Mounting screws for the windlass cover, four # 10 wood screws

Patience

For identification purposes please record the serial number, model number

and voltage of this anchor windlass and keep it in an accessible place. This in-

formation will be necessary if you need to contact IDEAL for any reason.

2

Contents

Packing

List

Tools

and

Materials

Required