26

Classic RS -

Installation & Servicing

SERVICING

Note.

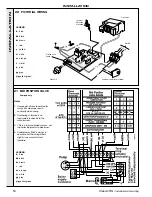

Refer also to Frame 53 of 'Exploded Views' for

illustration of the procedure detailed below.

cla 6034

Gas cock union

Gas cock

6

44 GAS CONTROL VALVE REPLACEMENT

1. Refer to Frame 36.

2. Remove the burner and air box assembly. Refer to Frame 43.

3. Remove the control box securing screws. Pull the box forward

and downward to disengage.

4. Remove the gas control valve electrical connection.

5. Disconnect and remove the gas union from the gas control

valve.

6. Whilst supporting the gas control valve, remove the 2

screws retaining the manifold to the back panel.

7. Remove the gas control / manifold assembly.

8. Remove the 4 screws retaining the manifold to the gas control

valve and fit the new manifold to the gas control valve, ensuring

that it is fitted the correct way round (an arrow engraved on the

back indicates the direction of flow).

Note.

Remove the gas cock stub and refit into the new gas

control valve. Use an approved jointing compound on the pipe

stub.

9. Reassemble in reverse order.

10. Replace the boiler casing.

11. Check the gas valve operation.

46 COMBUSTION CHAMBER INSULATION REPLACEMENT

1. Refer to Frame 36.

2. Remove the burner and air box

assembly. Refer to Frame 43.

3. Remove the 4 tie rods.

4. Remove the combustion chamber.

5. Remove the 2 side panel retaining

brackets.

6. Remove the side insulation panels.

7. Remove the front and rear

insulation panels.

8. Fit the new front and rear

insulation panels.

9. Fit the new side panels and

retain with the brackets and

screws previously removed.

10. Reassemble in reverse order.

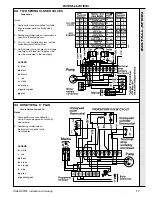

4. Transfer,

one by one (to avoid confusion), all push-in

connectors to the new PCB.

5. Compress the barbs on the PCB stand-offs to release the

PCB from the box.

6. Fit the new PCB and reassemble in reverse order.

7. Refit the boiler casing.

8. Check the operation of the boiler.

45 PRINTED CIRCUIT BOARD (PCB) REPLACEMENT

Note.

Refer to Frame 52 of 'Exploded Views' for

illustration of the procedure detailed below.

1. Refer to Frame 36.

2. Remove the control box fixing screws. Pull the box

forward and downward to disengage.

3. Remove the HT lead from the PCB.

SER

VICING