General information

4

WARNINGS

m

IMPORTANT

–

The appliance must be used for the purposes for which it has been expressly designed and any manufacturer’s liability shall

be excluded in case of damage to persons, animals or property due to insufficient maintenance or improper use.

–

This manual is an integral part of the Boiler and must be carefully read before installation and commissioning of the

appliance. Moreover, it must be carefully stored for subsequent consultations and must ALWAYS accompany the Boiler

during its entire life-cycle (from Installation to disposal). In case of damage or loss, request a copy from

ICI CALDAIE S.p.A.

Technical Assistance Service.

–

The appliance is delivered in several separated packages. Upon receipt, check that the supply is intact and undamaged and

promptly contact the

ICI CALDAIE S.p.A.

if it does not correspond to the order.

–

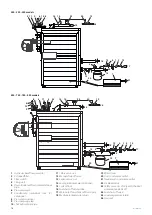

The installation of

MONOLITE GT

boilers must be performed by a Certified Company which, at the end of the operation,

must provide the owner with the declaration of conformity certifying that the installation has been correctly carried out,

namely in compliance with the Standards and the national and local Laws in force, and with the indications included in the

instruction manuals supplied by

ICI CALDAIE S.p.A.

.

–

The maintenance of the appliance is a legislative obligation. The User must have it carried out by an Authorised Company

or by qualified personnel (maintenance technician) in compliance with the requirements of the local Standards in force.

–

Ordinary and extraordinary maintenance must be carried out by qualified personnel in order to promptly detect any

damage to the boiler body under pressure and to the safety and control accessories.

PROHIBITIONS

d

IT IS FORBIDDEN

–

Operate electrical devices or appliances such as switches, household appliances, etc. if you smell fuel or unburnt materials.

In this case:

-

ventilate the room by opening doors and windows

-

close the fuel shut-off device

-

ask the Technical Assistance Service or qualified personnel to intervene as soon as possible.

–

Any technical or cleaning operation carried out before disconnecting the appliance from the power supply mains, by

positioning the system main switch and the control panel main switch to “OFF”.

–

Modifying safety or adjustment devices without the Boiler manufacturer’s authorisation and indications.

–

Plug or dimensionally reduce the ventilation openings of the installation room. The ventilation openings are essential for

proper combustion.

–

Exposing the Boiler to atmospheric agents. It is not designed to operate outdoor and it does not feature automatic anti-

freeze systems.

–

Leave flammable substances and containers in the room where the appliance is installed.

–

Disperse the packaging material in the environment and leave it within the reach of children as it may be a potential source

of danger. It must be disposed of in accordance with the legislation in force.