26

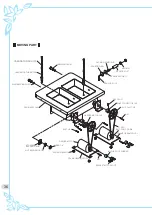

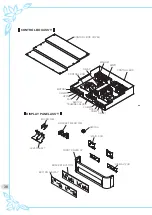

Removal and Replacement of Compressor

B. Removal and Replacement of Compressor

1. Always install a new drier every time the sealed refrigeration system is opened.

2. Do not replace the dried until after all other repair or replacement has been made.

Install the new drier with the arrow on the drier in th

3. When brazing, protect the drier and 4-way valve by using a wet cloth to provent the drier

and 4-way valve from overheating, Do not allow the drier to exceed 250

℉

(121

℃

)

When replacing the compressor with defective winding, replace the start capacitor and the start

relay as well.

The compressor shall be replaced and serviced within 15 minutes since the POE oil inside the

compressor rapidly absorbs moisture.

1) Turn off the power of ELCB.

2) Open the side door.

3) Recover the refrigerant using an adequate vessel.

4) Remove the terminal cover of the compressor and disconnect the compressor cable.

5) Remove the discharge and the suction pipes.

6) Remove the bolts, washers, and rubber grommets from the compressor.

7) Remove the compressor. Remove the packaging of the new compressor.

8) Insert the rubber grommets in the new compressor.

9) Place the compressor on the system and assemble it on the system by tightening the bolts

and the washers.

10) Replace the drier with a new one.

11) While purging with nitrogen gas at pressure of 3-4 psig, braze the copper connections.

12) Inject nitrogen at pressure of 140 psig and check for leaks with electric leak detector

or soap water.

13) Vacuum the system and inject the refrigerant.

14) Connect the terminal and assemble the terminal cover on its position.

15) Close the side door.

16) Turn on the power of ELCB.

WARING